Precision Laser Etching

Laser etching, also known as laser engraving, is a cutting-edge process that utilizes laser technology to create precise and permanent markings on various materials. With its exceptional accuracy and versatility, precision laser etching has become increasingly popular across industries such as manufacturing, electronics, automotive, and aerospace. In this article, we will explore the capabilities, applications, advantages, and considerations of precision laser etching.

What is Precision Laser Etching?

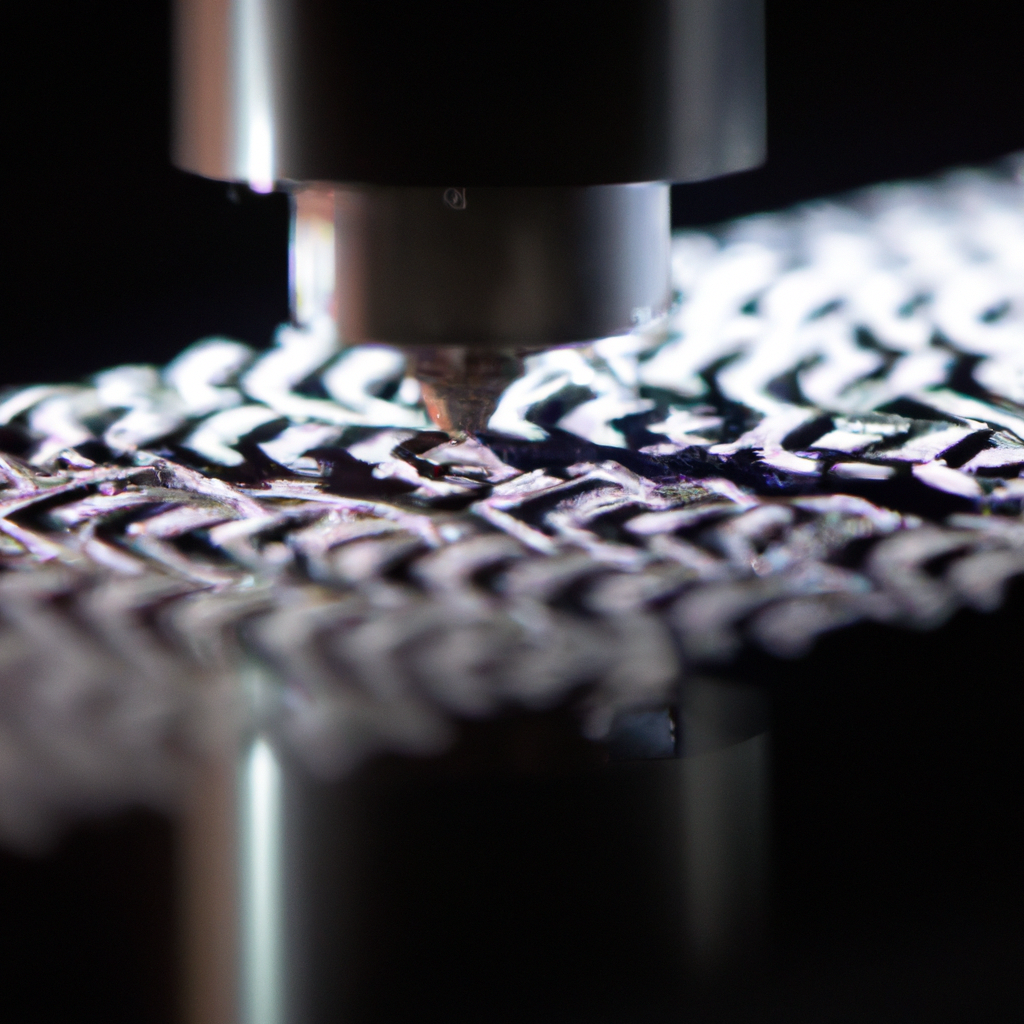

Precision laser etching is a technique that employs a high-powered laser beam to remove material from the surface of an object, leaving behind a permanent mark or design. This cutting-edge process utilizes the focused energy of the laser to create precise and detailed markings without the need for physical contact or the use of inks or dyes.

Applications of Precision Laser Etching

1. Product Identification and Branding

One of the primary applications of precision laser etching is product identification and branding. Manufacturers can use laser etching to inscribe logos, serial numbers, barcodes, and other essential information directly onto their products. This ensures traceability, enhances brand recognition, and helps prevent counterfeiting.

2. Personalization and Customization

Precision laser etching provides an ideal solution for personalized and customized items. Whether it’s engraving a piece of jewelry with a name or creating unique designs on electronic devices, laser etching offers unmatched flexibility and precision. This capability is particularly valuable in the gift and promotional industries.

3. Medical and Surgical Instruments

In the medical field, precision is of utmost importance. Laser etching allows for the precise marking of medical instruments, implants, and devices. This not only aids in identification and inventory management but also ensures patient safety by enabling easy traceability and reducing the risk of mix-ups during surgical procedures.

4. Aerospace and Automotive Components

Aerospace and automotive industries rely heavily on precision laser etching for component identification, tracking, and quality control. Laser etching provides permanent and tamper-proof markings on various materials, including metals and composites, ensuring the durability and longevity of the markings in demanding environments.

5. Electronics and Circuit Boards

Precision laser etching plays a vital role in the electronics industry. It enables the precise marking of circuit boards, microchips, and electronic components, ensuring proper assembly and identification. Laser etching can also be used for traceability, aiding in the repair and maintenance of electronic devices.

Advantages of Precision Laser Etching

Precision laser etching offers numerous advantages over traditional marking methods. Here are some key benefits:

1. High Precision and Accuracy

As the name suggests, precision laser etching offers exceptional precision and accuracy. The laser beam can achieve intricate details and minimal line widths, allowing for precise markings that are not possible with other conventional methods. This is particularly beneficial when working with small or delicate objects.

2. Non-Contact Process

Unlike mechanical engraving or printing methods, laser etching is a non-contact process. The laser beam does not physically touch the surface, eliminating the risk of damage or distortion to the object. This makes it an ideal choice for delicate materials, such as glass, ceramics, and semiconductors.

3. Versatility and Flexibility

Precision laser etching can be applied to a wide range of materials, including metals, plastics, glass, leather, wood, and more. This versatility makes it suitable for various industries and applications. Laser etching can also adapt to different shapes, sizes, and textures, allowing for customized markings on irregular surfaces.

4. Speed and Efficiency

Laser etching is a fast and efficient process. The laser beam operates at high speeds, allowing for quick marking of multiple objects in a short amount of time. This efficiency is especially valuable in high-volume production environments, where time is a critical factor.

5. Permanent and Durable Markings

With precision laser etching, the markings created are permanent and highly durable. They are resistant to wear, fading, and environmental factors, ensuring longevity and readability even in harsh conditions. This makes laser etching ideal for outdoor applications or items subject to frequent handling.

Considerations for Precision Laser Etching

While precision laser etching offers numerous benefits, there are a few considerations to keep in mind before opting for this marking method:

1. Material Compatibility

Not all materials are suitable for laser etching. Certain plastics, for example, may release toxic fumes when subjected to laser heat. It is essential to consider the material’s composition and consult with experts to ensure compatibility before proceeding with laser etching.

2. Design Complexity

The complexity of the desired design or marking can impact the cost and time required for precision laser etching. Highly intricate designs may require more laser passes and additional setup, increasing the overall production time and cost. Therefore, it is essential to consider the design complexity and consult with experienced professionals.

3. Surface Preparation

To achieve optimal results, the surface to be laser etched needs to be clean and free from contaminants. Any dirt, grease, or residue on the surface can interfere with the laser’s performance and result in subpar markings. Proper surface preparation, including cleaning and masking, is crucial for achieving high-quality laser etching.

In conclusion, precision laser etching is a cutting-edge technology that offers unparalleled accuracy, versatility, and durability in creating permanent markings on various materials. Its applications range from product identification and branding to personalized items, medical instruments, aerospace components, electronics, and more. With its numerous advantages and considerations, precision laser etching has become an invaluable tool in various industries, revolutionizing the way we mark and customize objects.