Precision Laser Engraving

Laser engraving has revolutionized the world of customization and personalization. Precision laser engraving is a cutting-edge technique that allows for intricate and detailed designs to be permanently etched on a variety of materials. From personalized gifts to industrial applications, precision laser engraving offers endless possibilities. In this article, we will delve into the world of precision laser engraving, exploring its applications, benefits, and the technology behind it.

What is Precision Laser Engraving?

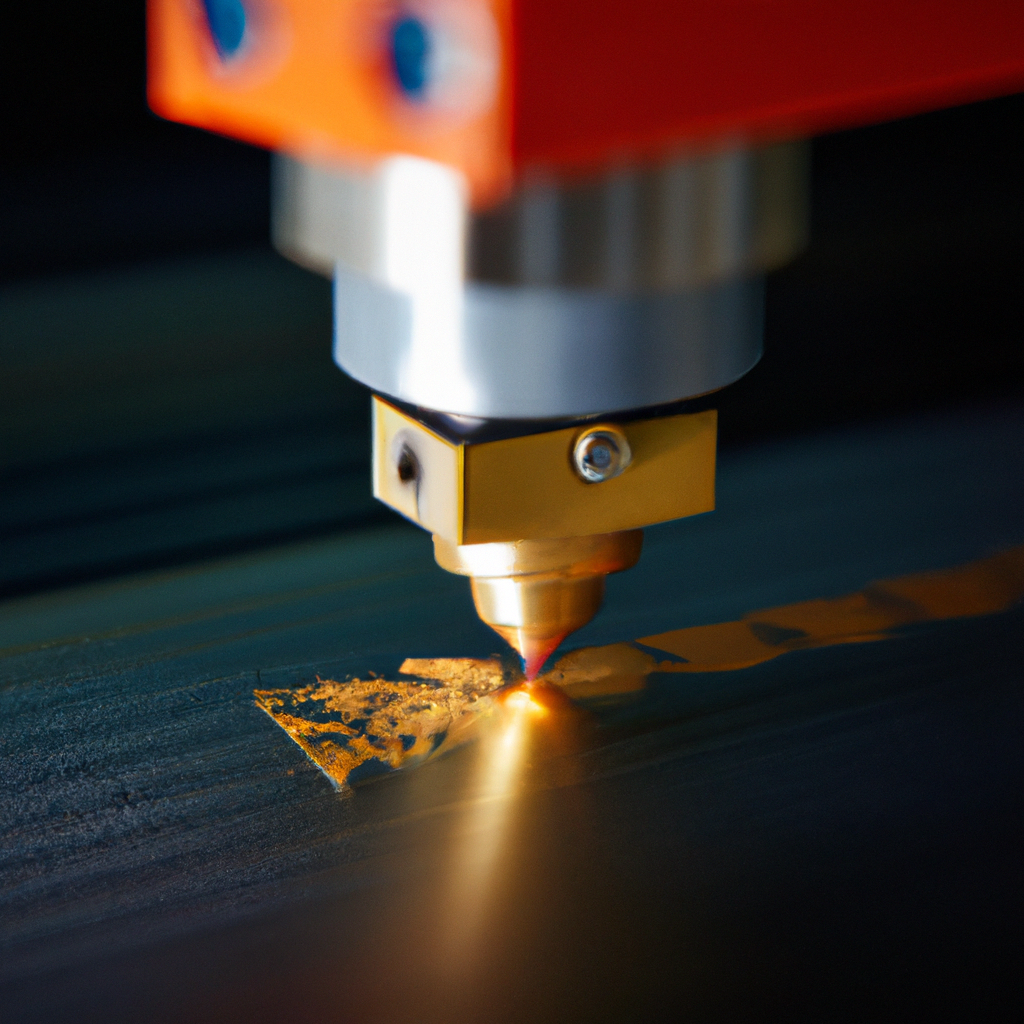

Precision laser engraving is a process that utilizes a high-powered laser beam to etch designs, text, or patterns onto various materials. Unlike traditional engraving methods, laser engraving offers unparalleled precision and accuracy, resulting in crisp and detailed markings. The laser beam removes the surface layer of the material, creating a permanent mark that is resistant to fading, peeling, or wearing off.

Applications of Precision Laser Engraving

-

Personalized Gifts: Precision laser engraving has become immensely popular in the world of personalized gifts. From engraved jewelry and photo frames to customized phone cases and cutting boards, laser engraving allows for unique and sentimental creations.

-

Industrial Marking: Precision laser engraving is widely used in industries for marking and branding products. Whether it’s serial numbers, barcodes, logos, or regulatory information, laser engraving provides a permanent and high-quality solution.

-

Promotional Items: Many businesses utilize precision laser engraving to create promotional items that leave a lasting impression. Customized pens, keychains, and USB drives with engraved logos or messages are highly sought after by companies looking to enhance their brand image.

-

Architectural Signage: Precision laser engraving is ideal for creating intricate designs and signage for architectural projects. From etching company logos on glass doors to engraving detailed patterns on metal panels, laser engraving adds a touch of sophistication and elegance.

-

Art and Design: Precision laser engraving has gained popularity among artists and designers. It allows them to transform their creative visions into reality by etching detailed designs on various materials, such as wood, acrylic, or leather.

Benefits of Precision Laser Engraving

-

Precision and Accuracy: As the name suggests, precision laser engraving offers unmatched precision and accuracy. It can create intricate designs with sharp edges and fine details, ensuring the desired outcome every time.

-

Versatility: Precision laser engraving can be applied to a wide range of materials, including wood, metal, glass, plastic, and even organic materials like leather or fabric. This versatility makes it suitable for various industries and applications.

-

Durability: Laser engraved markings are highly durable and resistant to fading, peeling, or wearing off. They can withstand harsh environmental conditions, making them ideal for both indoor and outdoor applications.

-

Non-Contact Process: Unlike traditional engraving methods, precision laser engraving is a non-contact process. The laser beam does not physically touch the material, minimizing the risk of damage or deformation.

-

High Efficiency: Laser engraving is a fast and efficient process. The laser beam operates at high speeds, enabling quick turnaround times for large-scale projects without compromising on quality.

The Technology Behind Precision Laser Engraving

Precision laser engraving relies on advanced laser systems that generate high-energy beams focused on a small spot size. These lasers are typically controlled by computer numerical control (CNC) systems, allowing for precise control of the engraving process. The laser settings, such as power, speed, and frequency, can be adjusted to achieve the desired depth and intensity of the engraved mark.

Lasers used in precision engraving are usually CO2 lasers or fiber lasers. CO2 lasers are well-suited for engraving organic materials like wood, leather, or acrylic, while fiber lasers are preferred for marking metals and hard plastics.

The design or artwork to be engraved is typically prepared using graphic design software or specialized engraving software. This digital file is then transferred to the laser engraving machine, which follows the designated path to create the desired design on the material’s surface.

Conclusion

Precision laser engraving has transformed the way we customize and personalize various materials. Its applications range from personalized gifts to industrial marking, architectural signage, and art and design. The benefits of precision laser engraving, such as accuracy, durability, and versatility, make it a popular choice for both individuals and businesses. With advanced laser systems and computer control, precision laser engraving offers limitless possibilities for creating intricate and permanent designs.