Laser Etching Technology

Laser etching technology has revolutionized many industries by offering precise and permanent marking solutions. With its versatile applications and high precision capabilities, laser etching has become an essential tool in various fields, including manufacturing, engineering, art, and more. In this article, we will explore the intricacies of laser etching technology, its benefits, and its applications in different industries.

How Laser Etching Works

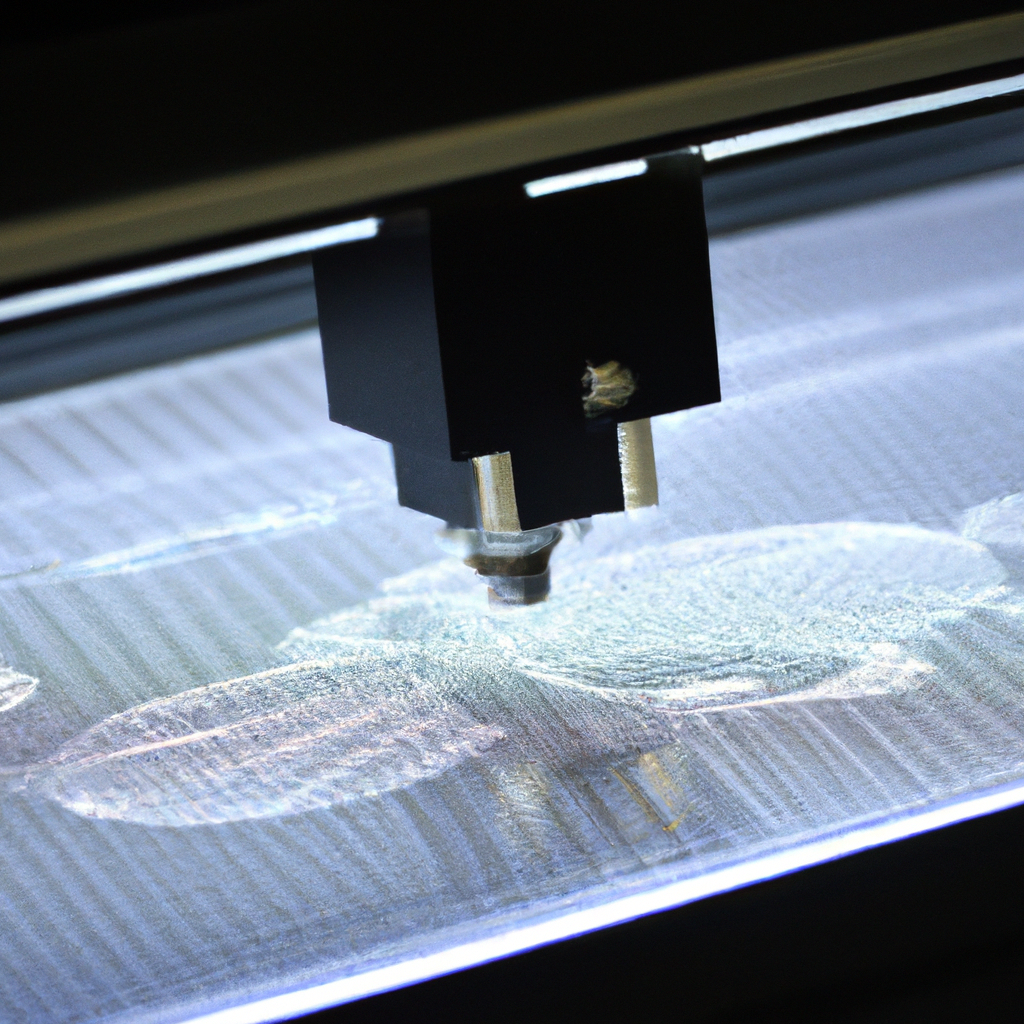

Laser etching, also known as laser engraving, is a process that uses focused laser beams to remove or vaporize materials from the surface of an object. The laser beam creates high heat and energy, which causes the targeted material to vaporize or undergo a chemical change, resulting in a permanent marking on the surface.

The process begins with the creation of a digital design or image that is then transferred to a computer-controlled laser etching machine. The machine uses a high-powered laser beam to follow the design and etch it onto the desired material. The laser etching machine’s precision and control allow for intricate designs, text, or graphics to be accurately reproduced on various materials.

Benefits of Laser Etching Technology

Laser etching technology offers numerous advantages over traditional marking methods. Some of the key benefits include:

-

High Precision: Laser etching provides incredibly precise and accurate markings, allowing for intricate designs and details to be reproduced consistently.

-

Versatility: Laser etching can be applied to a wide range of materials, including metals, plastics, glass, wood, leather, and more. This versatility makes it highly adaptable across different industries.

-

Durability: Laser-etched markings are incredibly durable and resistant to fading, wear, and harsh environmental conditions. They are long-lasting and maintain their quality over time.

-

Non-Contact Process: Unlike traditional engraving methods that require physical contact with the surface, laser etching is a non-contact process. This eliminates the risk of damage or deformation to delicate or sensitive materials.

-

Speed and Efficiency: Laser etching is a fast and efficient process that can complete intricate designs in a fraction of the time it would take using traditional methods. This makes it ideal for high-volume production environments.

-

Flexibility: Laser etching allows for the customization and personalization of products, enabling businesses to offer unique and tailored solutions to their customers.

Applications of Laser Etching Technology

Laser etching technology finds applications in various industries due to its versatility and precision. Some of the common applications include:

Manufacturing and Engineering

In the manufacturing and engineering sectors, laser etching is widely used for product identification, branding, and traceability. It enables manufacturers to mark serial numbers, logos, barcodes, and other essential information on their products. Laser etching can also be used to create precise and intricate patterns on metals, such as gears, tools, and components.

Art and Design

Artists and designers leverage laser etching technology to create unique and visually stunning pieces. It allows them to etch intricate designs, patterns, and textures on various materials, opening up new possibilities for creativity. Laser etching can be used on materials like acrylic, wood, glass, and even stone, enabling artists to push the boundaries of their creations.

Medical and Pharmaceutical

Laser etching plays a vital role in the medical and pharmaceutical industries. It is used for marking medical devices, surgical instruments, and pharmaceutical packaging. The permanent and high-quality markings facilitated by laser etching ensure accurate identification, inventory management, and traceability throughout the healthcare supply chain.

Electronics and Semiconductor

In the electronics and semiconductor industries, laser etching is crucial for marking components, circuit boards, and microchips. Laser etching allows for precise labeling, part identification, and brand marking. The non-contact nature of laser etching prevents any damage to delicate electronic components, ensuring their integrity and functionality.

Automotive and Aerospace

Laser etching technology is extensively used in the automotive and aerospace sectors for part identification, branding, and traceability purposes. It enables manufacturers to mark essential information on various components, such as engine parts, chassis, and aircraft parts. The permanent and durable markings provided by laser etching ensure efficient quality control, maintenance, and part replacement processes.

Conclusion

Laser etching technology has revolutionized the way we mark and engrave various materials. Its precise and permanent markings, along with its versatility and durability, make it an invaluable tool in numerous industries. From manufacturing and engineering to art and design, laser etching finds applications in diverse fields. As technology continues to advance, laser etching is expected to further evolve, offering even more possibilities for innovation and creativity.