Laser Etching Techniques

Laser etching is a precise and versatile method used to create detailed designs and patterns on various materials. This technique utilizes a laser beam to remove the surface layer of the material, resulting in a permanent and high-quality etch. From personalized gifts to industrial applications, laser etching offers numerous benefits and possibilities. In this article, we will explore different laser etching techniques and their applications.

1. CO2 Laser Etching

CO2 laser etching is one of the most commonly used techniques in the industry. This method uses a high-powered CO2 laser beam to engrave or etch materials such as wood, glass, acrylic, leather, and more. The CO2 laser interacts with the surface of the material, vaporizing and removing it to create the desired design.

Applications of CO2 Laser Etching:

- Personalized gifts: CO2 laser etching is often used to create customized designs on items like wood plaques, glassware, and leather wallets.

- Industrial labeling and markings: This technique is ideal for marking serial numbers, barcodes, and logos on various materials used in industries like automotive, electronics, and aerospace.

- Art and crafts: CO2 laser etching allows artists to create intricate designs and patterns on different materials, expanding their creative possibilities.

2. Fiber Laser Etching

Fiber laser etching is a highly precise technique that uses a fiber laser beam to engrave or mark materials. This method is particularly effective for metals like stainless steel, aluminum, brass, and titanium. The fiber laser’s high energy density enables precise and permanent markings on the surface of these materials.

Applications of Fiber Laser Etching:

- Metal engraving: Fiber laser etching is widely used for creating permanent and detailed marks, serial numbers, and logos on metal components, tools, and machinery parts.

- Medical and aerospace industries: The high precision of fiber laser etching makes it suitable for marking medical instruments, surgical implants, and aerospace components, where accuracy is crucial.

- Jewelry and watchmaking: This technique allows for intricate designs and personalized engravings on various types of metals used in jewelry and watchmaking.

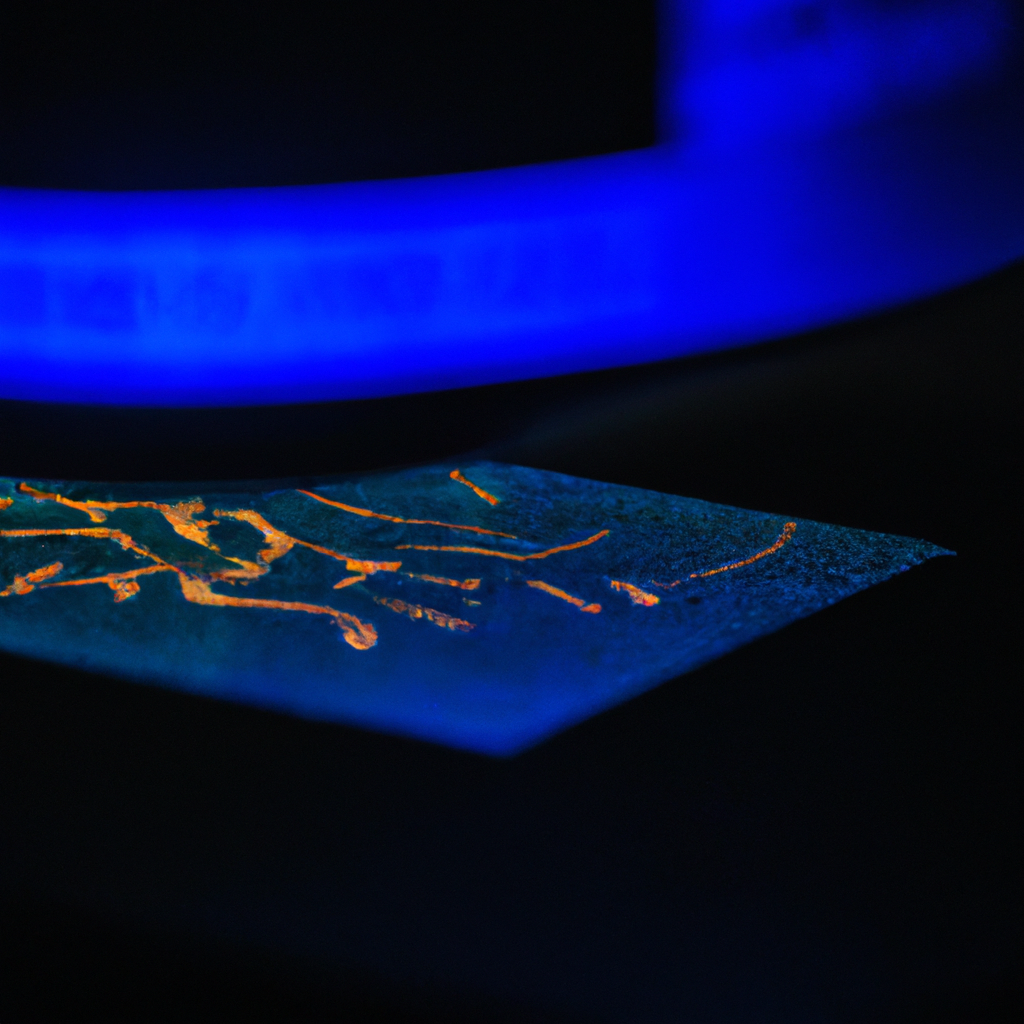

3. UV Laser Etching

UV laser etching is a versatile technique that utilizes an ultraviolet laser beam to mark or etch materials. This method is commonly used for sensitive materials like plastics, silicon, ceramics, and even certain metals. The shorter wavelength of the UV laser provides high-resolution etchings with minimal heat-affected zones.

Applications of UV Laser Etching:

- Electronics industry: UV laser etching is used for marking and etching circuit boards, microchips, and other electronic components due to its high precision and minimal heat transfer.

- Medical implants and devices: This technique enables precise markings on medical implants, surgical instruments, and medical devices made from materials like silicon or ceramics.

- Automotive and aerospace: UV laser etching is employed for marking and branding parts, components, and labels in the automotive and aerospace industries.

4. Green Laser Etching

Green laser etching is another effective technique used for marking and etching various materials. This method utilizes a green laser beam with a wavelength of 532 nm, which offers excellent visibility and high precision. Green laser etching is commonly used for materials like glass, ceramics, plastics, and metals.

Applications of Green Laser Etching:

- Glass and crystal engraving: Green laser etching allows for intricate and detailed engravings on glassware, trophies, and decorative items made from crystal.

- Electronics and semiconductors: This technique finds applications in marking circuit boards, semiconductors, and other electronic components due to its precision and clear visibility.

- Artistic engravings: Green laser etching is often used by artists to create unique and detailed designs on various materials, including wood, acrylic, and plastics.

Conclusion

Laser etching techniques provide endless possibilities for creating detailed and permanent designs on a wide range of materials. From CO2 laser etching for personalization and industrial applications to fiber, UV, and green laser etching for high-precision markings, each technique offers unique advantages. Whether you are looking to personalize a gift, create intricate artwork, or mark industrial components, laser etching is a versatile solution that delivers exceptional results.