Laser Etching Systems

Laser etching systems have revolutionized the way we personalize and mark various materials. From industrial applications to artistic creations, laser etching has become an essential tool for precision marking and engraving. In this article, we will delve into the world of laser etching systems, exploring their capabilities, applications, and benefits.

What are Laser Etching Systems?

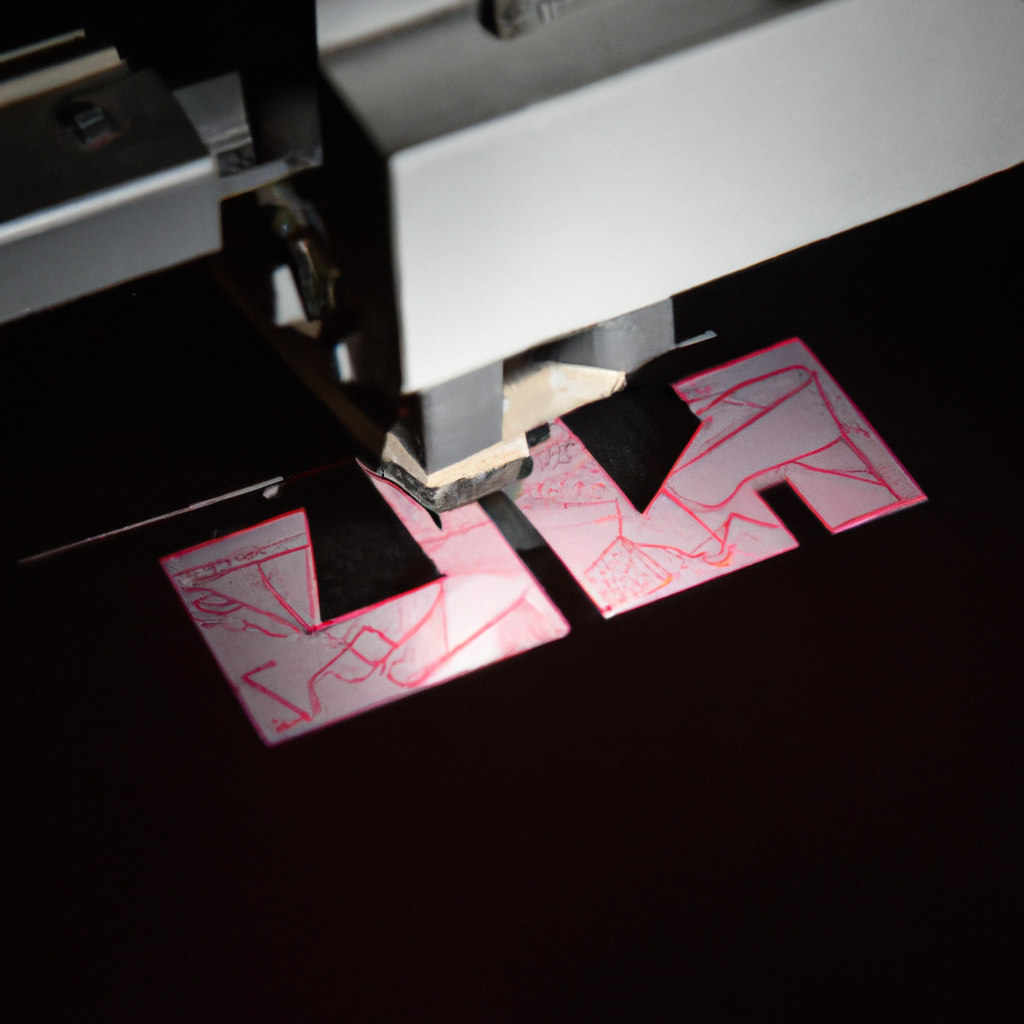

Laser etching systems utilize focused laser beams to create permanent markings on various surfaces. The process involves removing material from the surface to leave a clear and precise mark. These systems can etch intricate designs, logos, text, or even barcodes with exceptional precision and speed.

How do Laser Etching Systems Work?

Laser etching systems consist of three main components: a laser source, a controller, and a marking head. The laser source emits a high-powered laser beam that is controlled by the controller, which determines the speed, power, and movement of the laser beam. The marking head directs the laser beam onto the surface to create the desired mark.

The laser beam interacts with the material, causing it to heat up and vaporize. As the material evaporates, it leaves behind a permanent mark. The depth and intensity of the mark can be adjusted depending on the laser power and duration of exposure.

Applications of Laser Etching Systems

Laser etching systems find applications in a wide range of industries and sectors. Some of the key applications include:

1. Industrial Marking

In the industrial sector, laser etching systems are used for part identification, traceability, and branding. They can mark serial numbers, part numbers, logos, and other essential information directly onto various materials such as metal, plastic, glass, and ceramics. Laser etching ensures durability and resistance to fading or wear, making it an ideal solution for harsh environments.

2. Personalization and Customization

Laser etching systems have gained popularity in the realm of personalization and customization. From personalized gifts and jewelry to promotional items and trophies, laser etching provides a way to add a personal touch to any item. The precision and versatility of laser etching allow for intricate designs and details, making it a preferred choice for personalized products.

3. Art and Crafts

Artists and craftsmen have embraced laser etching as a medium for their creations. The ability to etch on various materials such as wood, acrylic, leather, and fabric opens up endless possibilities for artistic expression. Laser etching allows artists to create stunning designs, textures, and patterns, adding depth and uniqueness to their work.

4. Medical Devices and Instruments

In the medical industry, laser etching is used to mark surgical instruments, implants, and medical devices. The permanent markings ensure traceability, quality control, and patient safety. Laser etching systems offer high precision and accuracy, enabling manufacturers to meet the stringent requirements of the medical field.

5. Electronics and Semiconductor Industry

Laser etching plays a crucial role in the electronics and semiconductor industry. It is used for marking circuit boards, microchips, and other electronic components. The precise and non-contact nature of laser etching avoids any damage or distortion to delicate electronic parts, ensuring optimal functionality.

Benefits of Laser Etching Systems

Laser etching systems offer numerous benefits compared to traditional marking methods. Some of the key advantages include:

-

High Precision: Laser etching systems provide exceptional precision, allowing for intricate and detailed markings with minimal margin for error.

-

Versatility: These systems can etch on a wide range of materials, including metals, plastics, glass, ceramics, and more, offering versatility in application.

-

Durability: Laser etched markings are highly durable and resistant to fading, wear, and chemicals, ensuring long-lasting legibility.

-

Speed and Efficiency: Laser etching systems can mark at high speeds, enabling efficient production processes and reducing overall costs.

-

Non-contact Process: Laser etching is a non-contact process, eliminating the need for physical tools and reducing the risk of damage to delicate materials or components.

-

Environmentally Friendly: Laser etching is an environmentally friendly process as it does not involve the use of inks, solvents, or other harmful chemicals.

Conclusion

Laser etching systems have revolutionized the way we mark and personalize various materials. From industrial applications to artistic creations, these systems offer precision, versatility, and durability. The ability to etch on a wide range of materials with exceptional detail has made laser etching a preferred choice in various industries. As technology continues to advance, laser etching systems will undoubtedly play an increasingly important role in the world of marking and engraving.

This article is written in markdown format.