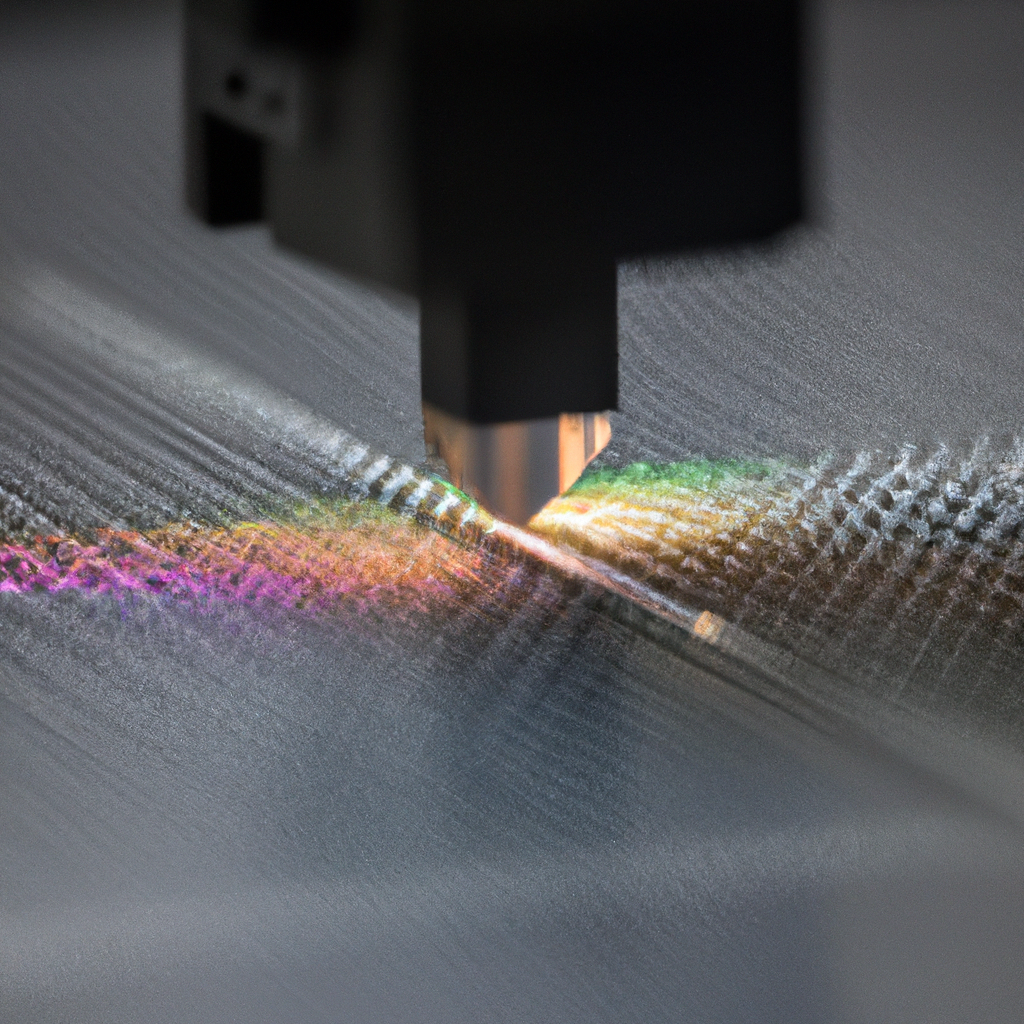

Laser Etching Process

Laser etching is a revolutionary technique that has gained popularity in various industries. It involves using a high-powered laser beam to engrave or mark a wide range of materials, including metals, plastics, glass, and even organic substances. This process offers precise and permanent results, making it a preferred choice for many applications. In this article, we will delve into the laser etching process, its applications, and the advantages it offers.

Understanding Laser Etching

Laser etching is a non-contact process that uses a focused laser beam to remove or displace material from the surface of an object, creating a permanent mark. The laser beam is generated by a laser machine and controlled by a computer program, allowing for incredible precision and accuracy.

The laser etching process involves several main steps:

-

Designing: The first step in laser etching is designing the artwork or pattern that will be etched onto the material. This can be done using computer-aided design (CAD) software or by importing existing images or text.

-

Preparing the Material: Before the actual etching process begins, the material needs to be properly prepared. This may involve cleaning the surface, applying a masking material to protect certain areas, or ensuring proper fixation.

-

Setting Parameters: Once the material is prepared, the laser machine needs to be set up according to the specific requirements of the material and the desired outcome. This includes selecting the appropriate laser power, speed, focus, and other parameters.

-

Etching: With all the settings in place, the laser beam is directed towards the material surface, where it removes or vaporizes a thin layer of material. The intensity and duration of the laser beam determine the depth and darkness of the etched mark.

-

Post-processing: After the etching is complete, post-processing may be required to remove any residue or markings left on the material. This can involve cleaning, polishing, or applying protective coatings, depending on the material and desired finish.

Applications of Laser Etching

The laser etching process offers a wide range of applications across various industries due to its versatility and precision. Some common uses include:

1. Product Branding and Identification

Laser etching is extensively used for branding and identifying products. Manufacturers can etch their logos, serial numbers, barcodes, or other essential information directly onto the product surface. This provides a permanent and tamper-proof marking solution that withstands wear, tear, and harsh environmental conditions.

2. Personalized Gifts and Artwork

Laser etching allows for intricate designs and personalized engravings, making it an ideal choice for creating unique gifts and artwork. From custom-engraved jewelry pieces to personalized wooden or glass items, laser etching adds a touch of exclusivity and elegance.

3. Industrial and Automotive Applications

The laser etching process finds extensive use in industrial and automotive applications. It is commonly used for marking and labeling components, such as circuit boards, engine parts, tools, and equipment. Laser-etched markings ensure easy identification, traceability, and compliance with industry standards.

4. Medical and Pharmaceutical Industry

In the medical and pharmaceutical industry, laser etching plays a crucial role in marking surgical instruments, medical devices, and pharmaceutical packaging. The permanent and legible markings provide vital information, such as batch numbers, expiry dates, and safety warnings.

5. Signage and Advertising

Laser etching enables the creation of high-quality signage and advertising materials. Whether it’s etching logos, promotional messages, or intricate designs on acrylic, glass, or metal surfaces, laser etching ensures durability and visual appeal.

Advantages of Laser Etching

The laser etching process offers numerous advantages over traditional marking methods. Some key benefits include:

-

Precision: Laser etching allows for extremely detailed and precise markings, creating intricate designs with micro-level accuracy.

-

Durability: Laser-etched marks are permanent and resistant to fading, scratching, and chemical exposure, ensuring longevity.

-

Versatility: The laser etching process is compatible with a wide range of materials, including metals, plastics, glass, ceramics, and more.

-

Speed and Efficiency: Laser etching is a fast and efficient process that can be automated, reducing production time and costs.

-

Non-contact: Unlike traditional engraving methods that involve physical contact, laser etching is a non-contact process, minimizing the risk of damage or deformation to delicate materials.

-

Eco-friendly: Laser etching is a clean and environmentally friendly process, as it does not require the use of inks, solvents, or chemicals.

Conclusion

Laser etching has revolutionized the way we mark and engrave various materials, offering precision, durability, and versatility. From industrial applications to personalized gifts and artwork, laser etching provides a wide range of possibilities. With its non-contact nature and numerous advantages, this process continues to gain popularity across industries. So, whether you need permanent branding, intricate designs, or detailed markings, laser etching is a reliable and effective solution.