Laser Etching Patterns

Laser etching has gained immense popularity in various industries due to its versatility and precision. It is a process that involves using a laser beam to engrave or mark various materials, creating intricate patterns, designs, or text. This article will explore the fascinating world of laser etching patterns, discussing their applications, benefits, and the different techniques used.

Applications of Laser Etching Patterns

Laser etching patterns find extensive use in numerous industries, thanks to their ability to add a touch of elegance, personalization, and functionality to various items. Here are some common applications:

1. Personalized Products

Laser etching allows individuals to personalize a wide range of products, including jewelry, accessories, and gifts. By engraving names, dates, or special messages, laser etching patterns add sentimental value and uniqueness to these items.

2. Branding and Marketing

Companies often utilize laser etching patterns to enhance their branding efforts. From engraving logos onto promotional products to customizing corporate gifts, laser etching helps create a lasting impression and reinforces brand identity.

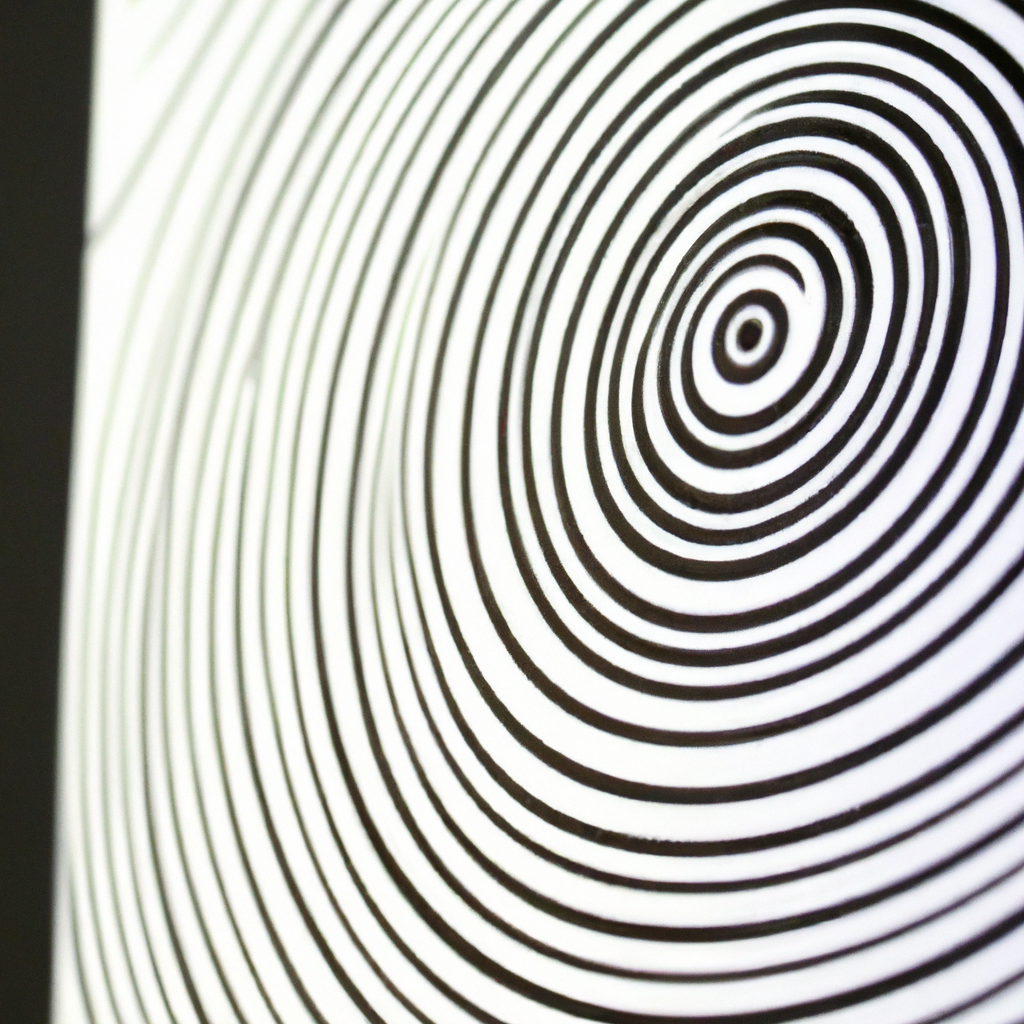

3. Art and Decor

Artists and designers embrace laser etching patterns to create stunning artworks and intricate designs on various materials such as wood, glass, or metal. These patterns can be highly detailed and visually captivating, adding a touch of sophistication to home decor or exhibitions.

4. Industrial Applications

In industries such as electronics, aerospace, and automotive, laser etching patterns play a vital role. By marking serial numbers, barcodes, or identification codes on components and parts, laser etching ensures traceability, facilitates inventory management, and assists in quality control.

Benefits of Laser Etching Patterns

The utilization of laser etching patterns offers several advantages over traditional engraving methods. Let’s delve into some notable benefits:

1. Precision and Detail

Laser etching patterns provide unparalleled precision and intricate detail, allowing for the creation of highly complex designs and text. The laser beam can accurately follow paths generated by computer software, resulting in consistent and flawless results.

2. Versatility

Laser etching patterns can be applied to a wide range of materials, including metals, plastics, glass, wood, and ceramics. This versatility makes it a preferred choice for various industries, ensuring that no matter the material, laser etching can deliver exceptional results.

3. Durability

Unlike traditional printing or engraving methods, laser etching patterns offer superior durability. The markings are resistant to fading, scratching, or smudging, ensuring that they remain intact even under harsh conditions. This durability makes laser etching ideal for industrial applications where longevity is essential.

4. Speed and Efficiency

Laser etching patterns are incredibly fast and efficient. The automated process of laser engraving allows for high production rates, reducing costs and lead times. Whether it’s a single item or a large batch, laser etching can handle the workload with ease.

Techniques Used in Laser Etching Patterns

Several techniques are employed to create laser etching patterns, each offering unique advantages depending on the desired outcome and material. Here are some commonly used techniques:

1. Vector Etching

Vector etching involves using linear paths to create sharp and precise lines. It is commonly used for text, logos, and simple designs. Vector etching is ideal for materials that allow for a deep and clean cut, such as wood or acrylic.

2. Raster Etching

Raster etching is a technique that utilizes a grid pattern to create shades, gradients, and complex designs. By varying the power and speed of the laser beam, different shades and depths can be achieved. Raster etching is commonly used for intricate artwork, photographs, or detailed patterns.

3. Halftone Etching

Halftone etching is a technique that creates images using a series of dots. It is often used to replicate photographs or grayscale images. By varying the density and size of the dots, the illusion of continuous tones is achieved, resulting in a visually appealing etched pattern.

4. Color Fill

Color fill is a technique used to enhance the visual impact of laser etching patterns. By adding paint or a specialized resin to the engraved areas, specific colors can be applied, creating contrast and highlighting the design. Color fill is commonly used in branding or artistic applications.

In conclusion, laser etching patterns offer endless possibilities for personalization, branding, artistic expression, and industrial applications. With their precision, versatility, durability, and efficiency, laser etching patterns have revolutionized the way we engrave and mark various materials. Whether it’s a small jewelry piece or a critical aerospace component, laser etching patterns provide a visually striking and long-lasting solution.