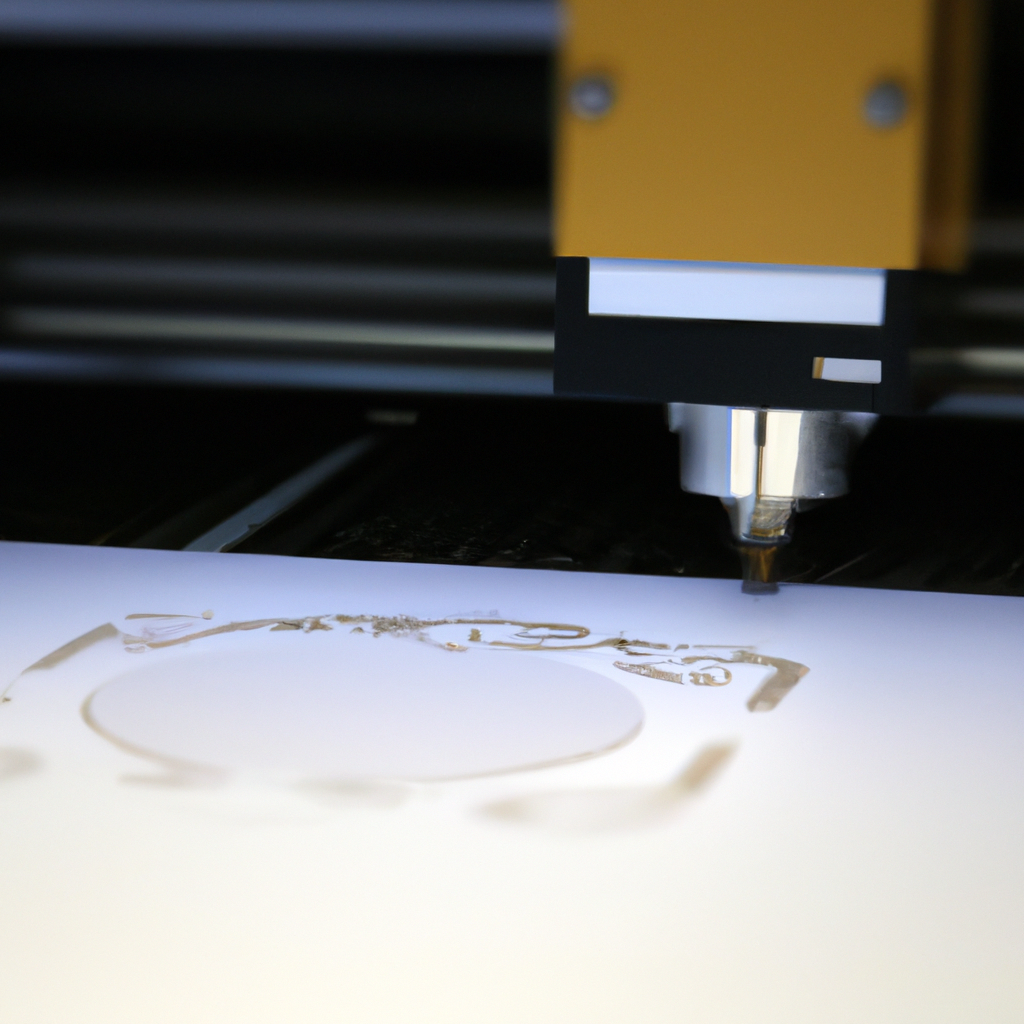

Laser Etching Machinery

Laser etching machinery has revolutionized the world of manufacturing and customization, allowing businesses to create intricate and precise designs on a wide range of materials. With its ability to engrave logos, serial numbers, or even intricate artwork on various surfaces, laser etching machinery has become an invaluable tool in numerous industries. In this article, we will delve into the world of laser etching machinery, exploring its functions, benefits, and applications.

What is Laser Etching Machinery?

Laser etching machinery utilizes focused laser beams to remove material from the surface of an object, creating permanent marks or designs. This process is achieved by heating the targeted area with a laser beam until it vaporizes or causes a chemical reaction, resulting in the desired engraving. These machines are equipped with advanced technology that allows for accurate and precise etching on various materials, including metals, plastics, glass, ceramics, and even organic materials.

How Does Laser Etching Machinery Work?

Laser etching machinery employs the principles of laser technology to accomplish its tasks. The process begins with a laser source that emits a powerful and concentrated beam of light. This laser beam is then directed through a series of mirrors and lenses to focus it into a small spot. The focused laser beam is then directed towards the surface of the material, where it interacts and removes material based on the desired design.

The laser beam can be controlled and manipulated through computer-aided design (CAD) software. This allows for precise control over the depth, intensity, and speed of the laser etching process. Furthermore, the machinery is equipped with a motion control system that ensures accuracy and consistency, enabling the creation of intricate and complex designs.

Benefits of Laser Etching Machinery

Laser etching machinery offers numerous advantages over traditional engraving methods. Here are some of its key benefits:

-

Precision and Accuracy: Laser etching machinery provides unmatched precision and accuracy, allowing for the creation of highly detailed and intricate designs. It can engrave fine lines, small text, and complex patterns with exceptional clarity.

-

Versatility: Laser etching machinery can be used on a wide range of materials, including metals, plastics, glass, and more. This versatility makes it an ideal choice for various industries, such as manufacturing, jewelry, electronics, and automotive.

-

Speed and Efficiency: Laser etching machinery can complete the engraving process quickly and efficiently. Its high-speed capabilities enable businesses to meet tight deadlines and increase productivity.

-

Non-contact Process: Laser etching machinery operates without any physical contact with the material. This reduces the risk of damage or distortion, making it suitable for delicate and sensitive items.

-

Permanent and Durable Marks: The marks created by laser etching machinery are permanent and highly durable. They resist fading, scratching, and other forms of wear, ensuring long-lasting results.

-

Flexibility: Laser etching machinery allows for easy customization and personalization. It can engrave unique designs, logos, or text, catering to individual customer preferences.

Applications of Laser Etching Machinery

The applications of laser etching machinery span a wide range of industries. Here are some notable examples:

Manufacturing and Industrial Applications

In the manufacturing sector, laser etching machinery plays a crucial role in product identification, branding, and traceability. It can engrave serial numbers, barcodes, or other identification codes on various parts, allowing for easy tracking and quality control. Laser etching is also used for engraving logos, product names, or safety instructions on consumer goods.

Jewelry and Fashion

The jewelry industry relies heavily on laser etching machinery for intricate engraving on precious metals, gemstones, and even watches. These machines enable the creation of unique designs, custom messages, and personalization, adding value and exclusivity to jewelry pieces.

Electronics

Laser etching machinery is widely used in the electronics industry to create permanent markings on circuit boards, semiconductor components, or electronic devices. It allows for precise labeling, part identification, and product branding.

Automotive and Aerospace

In the automotive and aerospace sectors, laser etching machinery is utilized for marking components, ensuring traceability, and enhancing security. It can engrave identification numbers, part numbers, or company logos on various metal and composite materials used in the manufacture of vehicles and aircraft.

Medical and Pharmaceutical

Laser etching machinery is employed in medical and pharmaceutical applications for marking surgical instruments, medical devices, and pharmaceutical packaging. It allows for clear identification, tracking, and compliance with regulatory requirements.

Conclusion

Laser etching machinery has revolutionized the way we engrave and customize materials. Its precision, versatility, and efficiency make it an essential tool across numerous industries, from manufacturing and jewelry to electronics and aerospace. With its ability to create permanent and durable marks on various materials, laser etching machinery has become an indispensable asset for businesses seeking high-quality, customized products.