Laser Engraving Techniques

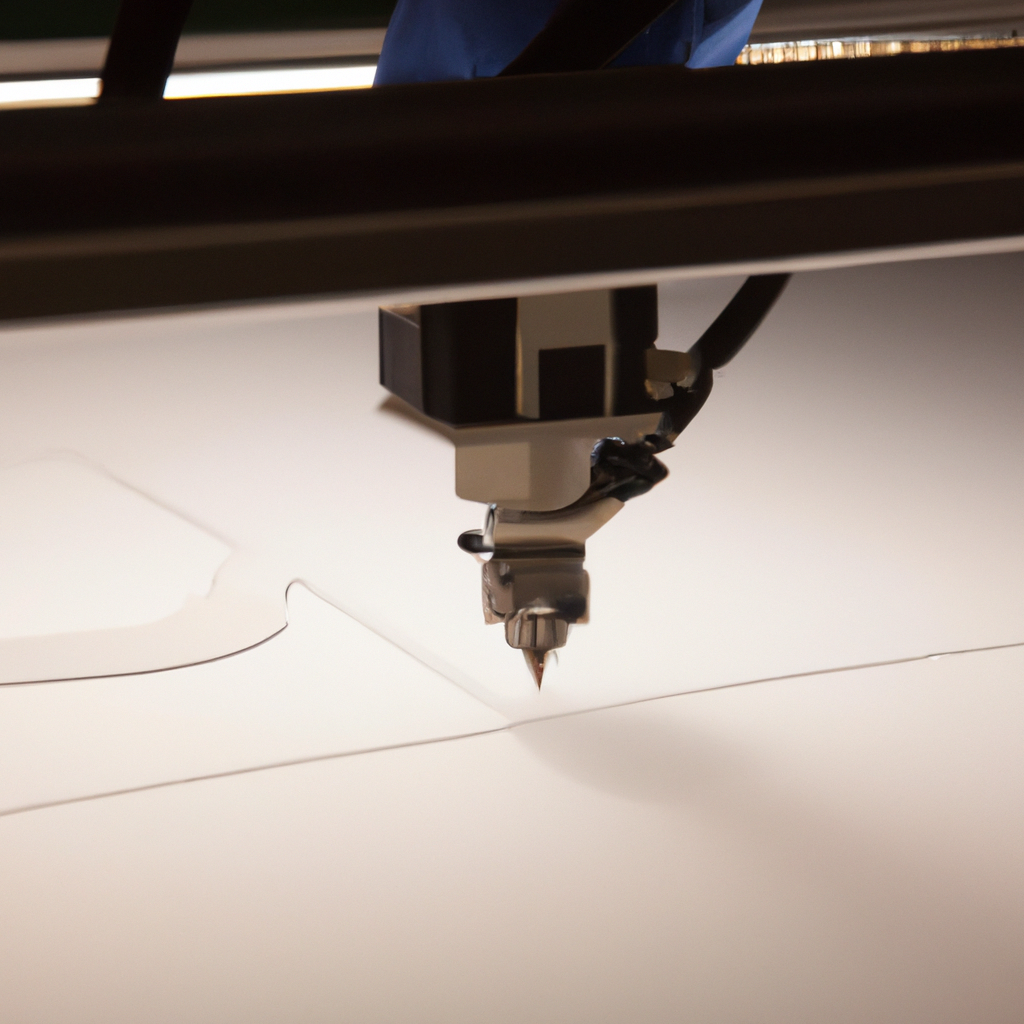

Laser engraving is a versatile and precise method of etching designs onto various materials, including wood, metal, glass, and plastic. This technique has gained immense popularity in recent years due to its efficiency, accuracy, and ability to create intricate and detailed designs. In this article, we will explore the different laser engraving techniques and delve into the benefits and applications of each.

1. CO2 Laser Engraving

CO2 laser engraving is one of the most common techniques used today. It involves using a high-powered CO2 laser to vaporize the surface of the material, resulting in a permanent etching. This method is ideal for engraving on organic materials such as wood, leather, and paper.

Benefits of CO2 Laser Engraving:

- High precision: CO2 lasers offer exceptional accuracy, allowing for intricate designs and fine details.

- Versatility: This technique can be employed on a wide range of materials, making it suitable for various applications.

- Speed: CO2 lasers are known for their fast engraving speeds, ensuring efficient production.

Applications of CO2 Laser Engraving:

- Personalized gifts: CO2 laser engraving enables the customization of items such as wooden plaques, leather wallets, and paper invitations, adding a personal touch to special occasions.

- Signage and branding: Businesses can utilize CO2 laser engraving to create eye-catching signage and brand their products with logos and information.

- Artistic expression: Artists can employ this technique to create stunning artwork on wood or paper, showcasing their talent and creativity.

2. Fiber Laser Engraving

Fiber laser engraving is a highly efficient technique that utilizes a fiber optic laser to etch designs onto metal and plastic surfaces. This method is widely used in industries such as automotive, aerospace, and electronics.

Benefits of Fiber Laser Engraving:

- Permanent and durable: Fiber laser engraving creates deep and long-lasting marks on metal and plastic, ensuring their durability.

- High-speed engraving: Fiber lasers can engrave at incredibly fast speeds, making them ideal for industrial applications.

- Non-contact process: This technique does not require any physical contact with the material, minimizing the risk of damage.

Applications of Fiber Laser Engraving:

- Identification and traceability: Fiber laser engraving is commonly used to mark serial numbers, barcodes, and other identification codes on metal components, facilitating traceability and quality control.

- Electrical components: The high precision of fiber lasers allows for the engraving of intricate designs on circuit boards and other electronic components.

- Automotive industry: Fiber laser engraving is employed in the production of car parts, such as engine components and control panels, providing clear and permanent labeling.

3. Diode-Pumped Laser Engraving

Diode-pumped laser engraving is a technique that utilizes diode-pumped solid-state lasers to etch designs on a variety of materials. This method is especially suitable for engraving on hard surfaces such as glass and ceramics.

Benefits of Diode-Pumped Laser Engraving:

- Versatility: Diode-pumped lasers can engrave on various materials, including glass, ceramics, and metals.

- Precision: This technique allows for precise and intricate engraving, making it perfect for delicate designs.

- Minimal heat transfer: Diode-pumped lasers produce minimal heat, reducing the risk of damaging sensitive materials.

Applications of Diode-Pumped Laser Engraving:

- Glassware and awards: Diode-pumped lasers can engrave intricate designs on glassware, such as wine glasses and trophies, adding a touch of elegance and personalization.

- Jewelry and watches: This technique is used to engrave intricate patterns, names, or logos on jewelry and watch surfaces, enhancing their aesthetic appeal.

- Electronic devices: Diode-pumped lasers can mark identification codes or branding on electronic devices, ensuring product authenticity.

In conclusion, laser engraving techniques offer a range of options for creating customized and permanent designs on various materials. Whether you prefer the versatility of CO2 laser engraving, the efficiency of fiber laser engraving, or the precision of diode-pumped laser engraving, there is a technique to suit your needs. Explore the possibilities of laser engraving and unlock endless creative opportunities.