Laser Engraving for Medical Devices

Laser engraving has become an indispensable tool in the medical industry, especially when it comes to marking and labeling medical devices. With its precision and versatility, laser technology offers numerous benefits for the healthcare sector. In this article, we will delve into the world of laser engraving for medical devices, exploring its applications, advantages, and how it contributes to enhancing patient safety and improving healthcare practices.

Introduction to Laser Engraving

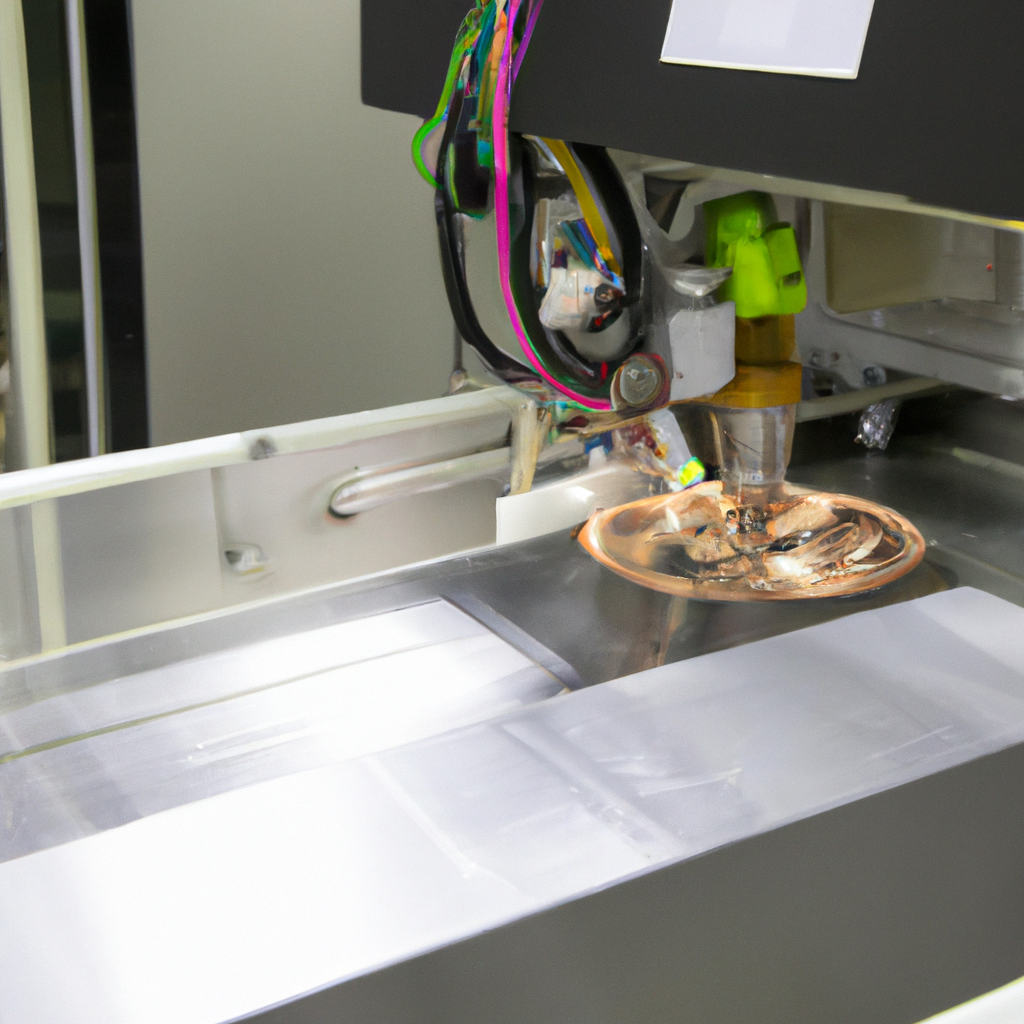

Laser engraving is a precise and non-contact marking technique that utilizes laser technology to create permanent markings on various materials. When it comes to medical devices, laser engraving is primarily used for labeling, branding, and identification purposes. The process involves the use of a high-powered laser beam that vaporizes the material’s surface, resulting in a permanent, high-contrast mark.

Applications of Laser Engraving in the Medical Field

1. Instrument Marking and Identification

Laser engraving offers a reliable method for marking surgical instruments, allowing for easy identification and traceability. Each instrument can be engraved with unique identifiers, such as serial numbers or barcodes, helping to streamline inventory management and ensure proper instrument tracking throughout their lifecycle. Moreover, laser engraving ensures that the marks remain legible even after repeated sterilization cycles, maintaining the integrity of the identification process.

2. Medical Device Branding and Logo Marking

Branding plays a crucial role in the medical device industry, as it helps manufacturers establish their identity and build trust with healthcare professionals and patients. Laser engraving enables precise and permanent marking of company logos, product names, and important information on medical devices. This branding not only enhances the overall appearance of the devices but also ensures clear identification and differentiation in a competitive market.

3. Regulatory Compliance and UDI Marking

In recent years, regulatory bodies, such as the U.S. Food and Drug Administration (FDA), have mandated the use of Unique Device Identification (UDI) systems for medical devices. Laser engraving provides an efficient and accurate way to mark these UDIs on various devices, including implants, surgical tools, and prosthetics. By implementing laser engraving for UDI marking, medical device manufacturers can ensure compliance with regulations, enhance patient safety, and facilitate device traceability throughout their lifecycle.

4. Anti-Counterfeiting Measures

Counterfeit medical devices pose a significant threat to patient safety and the reputation of manufacturers. Laser engraving offers a powerful solution to combat counterfeiting by providing a tamper-evident marking method. The precision and permanency of laser engravings make it difficult for counterfeiters to replicate or alter markings, thus ensuring the authenticity and integrity of medical devices.

Advantages of Laser Engraving for Medical Devices

1. Precision and Permanence

Laser engraving offers unparalleled precision, allowing for intricate and detailed markings on various materials, including metals, plastics, and ceramics. The use of lasers ensures consistent depth and clarity in the engravings, making them easily readable and durable. This permanence is particularly critical for medical devices that undergo frequent sterilization processes.

2. Non-Contact and Non-Destructive

Unlike traditional engraving methods that involve physical contact with the material, laser engraving is a non-contact process. This non-destructive nature eliminates the risk of damaging delicate medical devices during the marking process. Additionally, the absence of physical contact reduces the need for frequent maintenance or replacement of tools, making laser engraving a cost-effective choice for medical device manufacturers.

3. Versatility and Flexibility

Laser engraving systems offer versatility in terms of mark design and size. Whether it is a small barcode or a complex logo, laser technology can accommodate various marking requirements. Furthermore, laser engraving can be performed on curved or irregular surfaces, allowing for the engraving of complex medical device geometries. This flexibility makes laser engraving an ideal choice for a wide range of medical devices, regardless of their shape or size.

4. Time and Cost Efficiency

Laser engraving is a highly efficient process that requires minimal setup time and allows for high-speed marking. With the ability to automate and integrate laser systems into production lines, medical device manufacturers can achieve increased productivity and reduced lead times. Moreover, laser engraving eliminates the need for consumables, such as inks or labels, resulting in long-term cost savings.

Conclusion

Laser engraving has revolutionized the medical industry by providing a reliable and efficient method for marking and labeling medical devices. From instrument identification to branding and regulatory compliance, laser technology offers numerous advantages that contribute to enhancing patient safety, improving inventory management, and combating counterfeiting. With its precision, permanence, and versatility, laser engraving continues to play a vital role in the advancement of medical device manufacturing, ensuring the highest standards of quality and traceability.