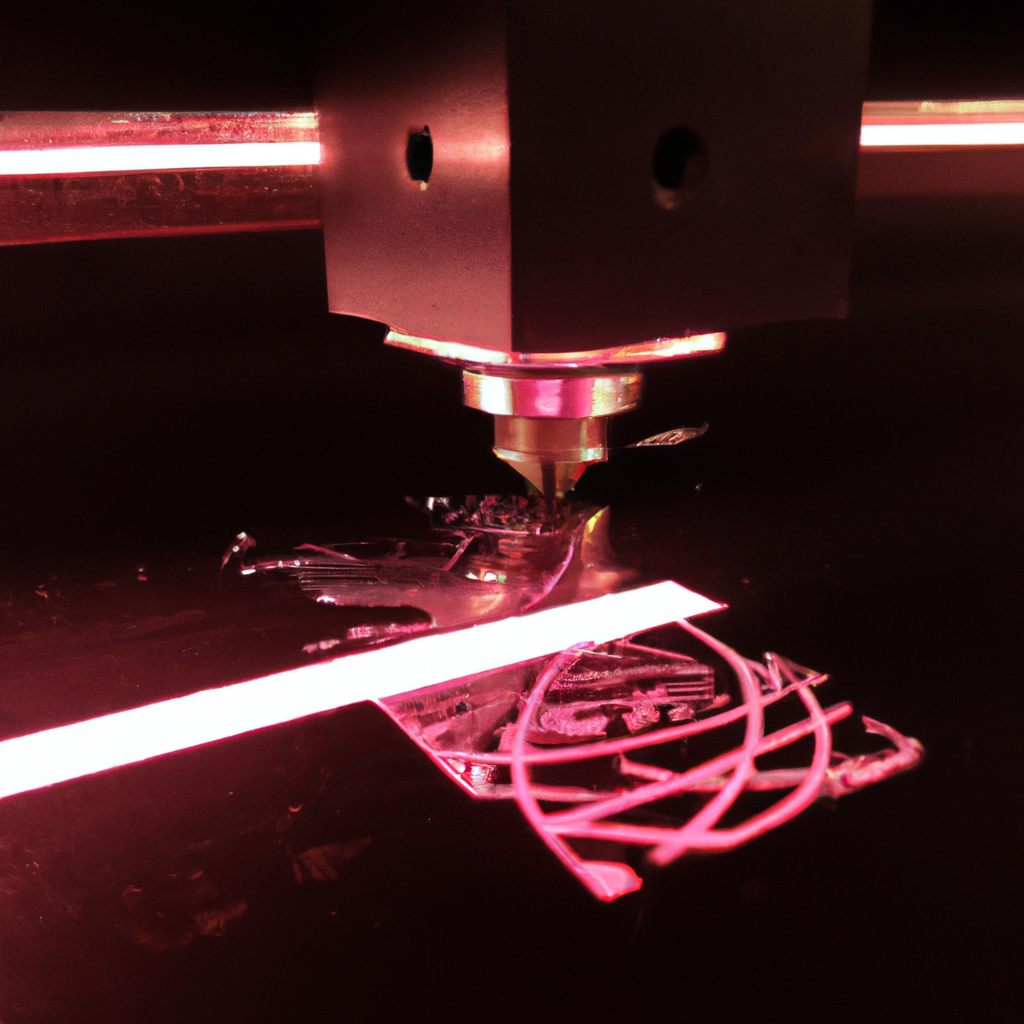

Laser Engraving for Industrial Use

Laser engraving has revolutionized the industrial sector, providing an efficient and precise method for marking and engraving various materials. This advanced technology utilizes laser beams to etch or engrave designs, logos, serial numbers, and other markings onto surfaces. With its versatility and accuracy, laser engraving has become a popular choice for a wide range of industries, including manufacturing, automotive, aerospace, and electronics.

Benefits of Laser Engraving

Laser engraving offers numerous advantages over traditional engraving methods, making it a preferred choice for industrial applications. Here are some key benefits:

1. Precision and Accuracy

Laser engraving ensures exceptional precision and accuracy, resulting in high-quality, detailed markings. The laser beam can be precisely controlled, allowing for intricate designs and fine details, even on small or delicate components. This level of precision is crucial, particularly in industries where clear and readable markings are essential.

2. Versatility

One of the remarkable features of laser engraving is its versatility. It can be used on a wide range of materials, including metals (such as stainless steel, aluminum, and titanium), plastics, glass, ceramics, wood, and even some fabrics. This flexibility makes laser engraving suitable for various industrial applications, from marking product identification codes to creating intricate designs on promotional items.

3. Durability

Laser engraved markings are highly resistant to wear, fading, and damage, ensuring their longevity. This durability is vital in industries where products are exposed to harsh environments, such as outdoor equipment or automotive components. The laser engraving process creates deep, permanent markings that withstand the test of time, making it an ideal choice for industrial use.

4. Non-Contact Process

Unlike traditional engraving methods that involve physical contact between the tool and the material, laser engraving is a non-contact process. By eliminating the need for direct contact, laser engraving reduces the risk of damage to delicate or sensitive parts, ensuring consistent and high-quality results every time. This non-contact approach also minimizes the need for costly maintenance and replacement of engraving tools.

5. Speed and Efficiency

Laser engraving offers exceptional speed and efficiency, making it an ideal choice for high-volume production lines. The process is automated, allowing for rapid and accurate engraving of multiple parts in a short period. This significantly improves productivity and reduces production time, ultimately leading to cost savings for industrial manufacturers.

6. Environmental Friendliness

Compared to traditional engraving methods that often involve the use of chemicals, laser engraving is an environmentally friendly solution. It is a clean and precise process that does not generate hazardous waste or emit harmful fumes. This eco-friendly characteristic aligns with the growing focus on sustainability and responsible manufacturing practices.

Applications of Laser Engraving in Industry

Laser engraving finds its application in various industrial sectors. Some notable applications include:

1. Product Identification and Branding

Laser engraving is extensively used for product identification and branding purposes. Manufacturers can engrave serial numbers, barcodes, logos, and other essential information directly onto their products, ensuring traceability and brand recognition. This helps in inventory management, quality control, and anti-counterfeiting measures.

2. Aerospace and Automotive Industries

The aerospace and automotive industries require durable and precise markings on various components and parts. Laser engraving provides a reliable solution for engraving part numbers, specifications, and safety information onto materials such as metals and plastics. These markings aid in assembly, maintenance, and ensuring the traceability of critical parts.

3. Medical and Pharmaceutical Devices

In the medical and pharmaceutical sectors, laser engraving is used for marking essential information on instruments, implants, and packaging. This includes serial numbers, lot codes, and expiration dates. Laser engraving ensures the durability and readability of these markings, contributing to patient safety and regulatory compliance.

4. Electronics and Semiconductors

Laser engraving plays a crucial role in the electronics and semiconductor industries, where precise marking on circuit boards, integrated circuits, and electronic components is vital. The non-contact nature of laser engraving minimizes the risk of damage to delicate electronic parts during the marking process, ensuring the integrity and functionality of the devices.

5. Promotional Items and Personalization

Laser engraving offers a unique and personalized touch to promotional items, corporate gifts, and personal accessories. It allows for the customization of products with names, logos, or personalized messages, enhancing their perceived value and appeal. This makes laser engraving an excellent choice for businesses looking to create memorable and distinctive marketing materials.

Conclusion

Laser engraving has become an indispensable tool in the industrial sector, providing unmatched precision, versatility, and durability for various applications. Its non-contact nature, speed, and efficiency make it an ideal choice for high-volume production lines, while the environmentally friendly aspect aligns with sustainable manufacturing practices. From aerospace and automotive industries to medical and electronics sectors, laser engraving continues to transform the way products are marked and branded. As technology evolves, laser engraving is expected to further advance, offering even more possibilities for industrial use.