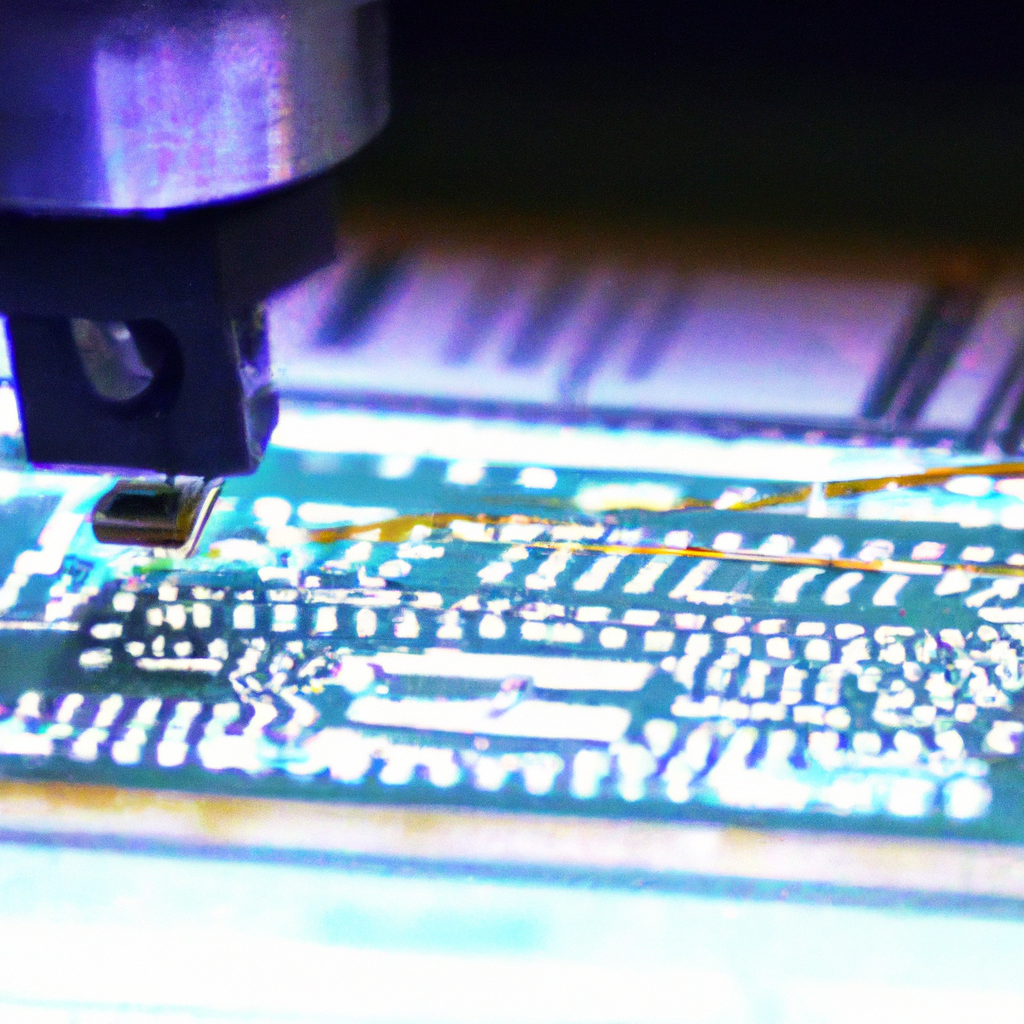

Laser Engraving for Electronics

In today’s fast-paced world, the demand for personalized and unique electronic devices is rapidly increasing. Laser engraving has emerged as a popular technique to achieve this customization, allowing individuals to add their personal touch to various electronic gadgets. This article will delve into the world of laser engraving for electronics, exploring its benefits, applications, and the technology behind it.

Understanding Laser Engraving

Laser engraving is a process that utilizes a concentrated beam of light to etch or mark surfaces with high precision. It works by removing layers of material through vaporization or melting, leaving behind a permanent mark. This technique allows for intricate designs, logos, serial numbers, or other personalized information to be engraved on different materials, including metals, plastics, glass, and even some organic materials.

Advantages of Laser Engraving

- Durability: Laser-engraved markings are highly durable and resistant to fading, scratching, or rubbing off, ensuring long-lasting personalization on electronic devices.

- Precision and Detail: Laser engraving allows for intricate and precise designs, ensuring that even the smallest details are accurately engraved on the surface of the electronics.

- Versatility: Laser engraving can be performed on various materials, making it suitable for a wide range of electronic devices, including smartphones, laptops, tablets, and wearables.

- Customization: With laser engraving, individuals can personalize their electronic devices by adding their names, images, patterns, or even custom designs, enhancing their uniqueness and aesthetics.

- Professional Appearance: Laser engraving provides a professional and high-quality finish, giving electronic devices a premium look and feel.

- Non-Contact Process: As laser engraving is a non-contact process, there is no physical interaction between the laser and the surface, minimizing the risk of damage to delicate electronic components.

Applications of Laser Engraving in Electronics

Personal Electronic Devices

Laser engraving offers endless possibilities for personalizing personal electronic devices, such as smartphones, tablets, and laptops. Users can engrave their names, initials, or unique designs, transforming their devices into personalized accessories.

Corporate Branding and Promotions

Electronics manufacturers and retailers can utilize laser engraving to engrave their logos, brand names, or promotional messages on devices. This not only enhances brand visibility but also adds value to the products, making them stand out from the competition.

Security and Anti-Counterfeiting Measures

Laser engraving can be employed as a security measure to deter counterfeiting and unauthorized tampering. Serial numbers, barcodes, or unique identifiers can be laser-engraved on electronic components to ensure traceability and authenticity.

Customization for Specialized Industries

In specialized industries like medical devices or aerospace, laser engraving plays a crucial role. It allows for the permanent marking of critical information, such as part numbers, specifications, or manufacturing codes, ensuring accurate identification and traceability.

Laser Engraving Technology

Laser engraving machines are equipped with high-powered lasers that emit a highly focused beam of light. The most commonly used lasers for engraving electronics include fiber lasers, CO2 lasers, and diode-pumped solid-state (DPSS) lasers. Each type of laser has its own unique characteristics, such as wavelength and power output, making them suitable for different materials and applications.

The laser beam is controlled by computer software, precisely directing it to the desired locations for engraving. This computer-controlled process ensures consistent and accurate results, even for complex designs.

Precautions and Considerations

While laser engraving offers numerous benefits, it is essential to consider a few precautions:

- Material Compatibility: Not all materials are suitable for laser engraving. It is crucial to determine the compatibility of the material with the laser and ensure it does not release toxic fumes or damage the laser equipment.

- Safety Measures: Laser engraving machines emit a powerful beam of light that can be harmful to the eyes and skin. Proper safety precautions, such as wearing protective eyewear and gloves, should be taken while operating the equipment.

- Surface Preparation: The surface to be engraved should be clean, free from dust, oils, or any other contaminants that may affect the quality of the engraving.

- Machine Settings: The laser power, speed, and focus must be appropriately adjusted for different materials to achieve the desired engraving results.

Conclusion

Laser engraving has revolutionized the personalization and customization of electronic devices, offering a wide array of possibilities for individuals and businesses alike. Its durability, precision, versatility, and professional appearance make it the ideal choice for adding a personal touch to electronic gadgets. By understanding the technology, applications, and precautions associated with laser engraving, one can explore the endless opportunities it presents in the world of electronics customization.