Laser Engraving for Barcodes

Laser engraving is a highly efficient and precise method used for marking various materials with permanent identification, including barcodes. This technology has revolutionized the way industries encode information on products, providing a reliable and versatile solution for businesses of all sizes. In this article, we will explore the benefits, applications, and considerations of laser engraving for barcodes.

Understanding Barcode Engraving

Barcodes are essential for product identification and tracking in industries such as manufacturing, logistics, and retail. They contain valuable information in a machine-readable format, enabling businesses to automate processes, improve inventory management, and enhance overall efficiency. Traditionally, barcodes were printed using inkjet or thermal transfer methods. However, laser engraving has emerged as a superior alternative due to its exceptional precision and durability.

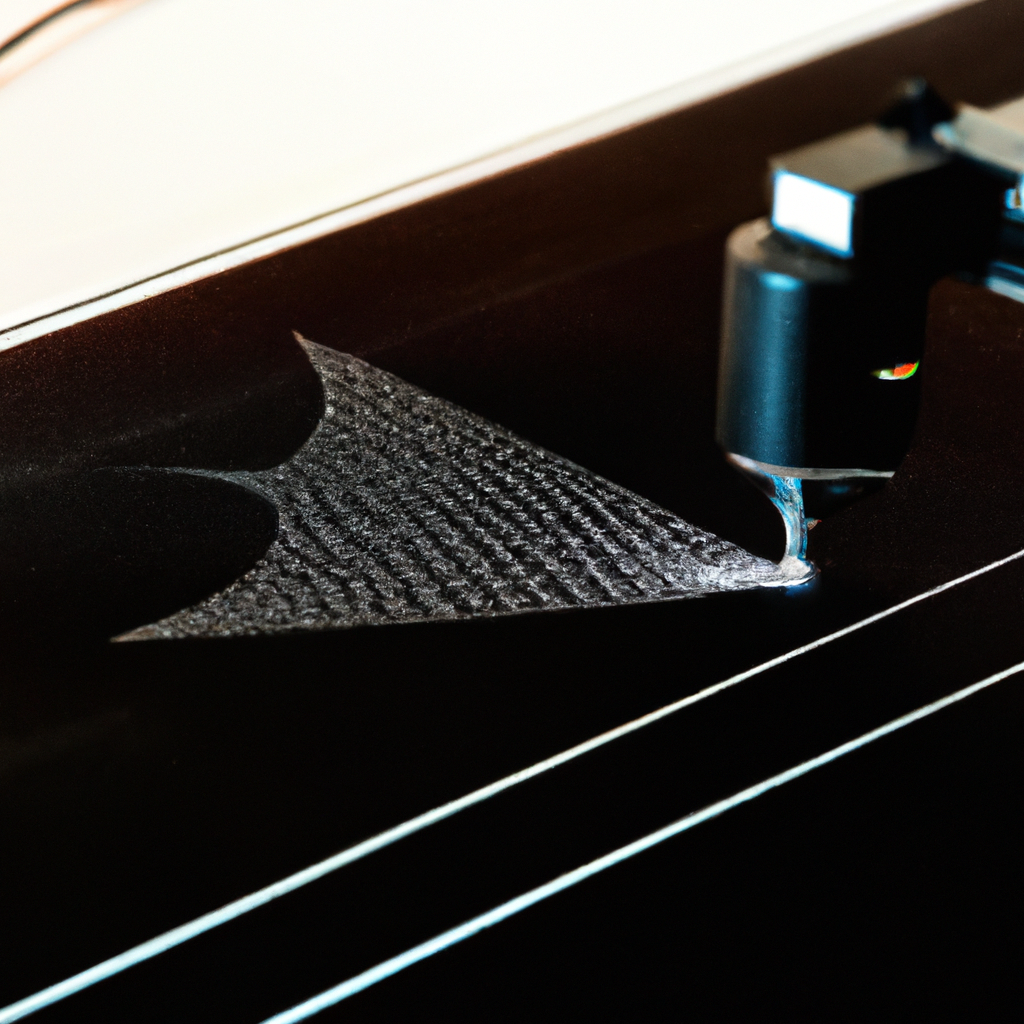

Laser engraving involves using a high-powered laser to etch or remove material from the surface of an object, creating a permanent mark. The laser emits a focused beam of light that vaporizes or ablates the material, leaving a precise and high-definition barcode. This process offers several advantages over traditional printing methods, as discussed below.

Benefits of Laser Engraving for Barcodes

1. Durability and Longevity

Laser-engraved barcodes are highly resistant to wear and tear. Unlike printed barcodes that can fade or smudge over time, laser engraving creates a permanent mark that withstands harsh environments, such as exposure to chemicals, moisture, and abrasion. This durability ensures that barcodes remain legible throughout the product’s lifecycle, reducing the chances of errors in scanning and data collection.

2. High Precision and Clarity

Laser engraving technology enables the creation of high-resolution barcodes with exceptional clarity. The focused laser beam ensures precise lines and edges, resulting in sharp, well-defined barcode symbols. This level of accuracy enhances barcode readability, preventing scanning errors and improving overall efficiency in automated processes.

3. Versatility and Adaptability

Laser engraving can be applied to a wide range of materials, including metals, plastics, ceramics, and composites. This versatility makes it suitable for various industries and diverse product types. Whether you need to mark barcodes on metal parts, plastic containers, or even glass surfaces, laser engraving can provide a reliable and adaptable solution.

4. High-Speed Processing

Modern laser engraving systems are equipped with advanced technology that allows for high-speed processing. This means that a large number of barcodes can be engraved quickly and efficiently, ensuring optimal productivity in industrial environments. The fast processing capabilities of laser engraving machines make it a cost-effective solution for high-volume barcode production.

5. Eco-Friendly Solution

Laser engraving is an environmentally friendly solution as it does not require the use of inks, solvents, or other harmful substances. Unlike traditional printing methods, there is no need for consumables, reducing waste generation and minimizing the environmental impact. By choosing laser engraving for barcodes, businesses can contribute to sustainable practices while maintaining the highest quality standards.

Applications of Laser Engraving for Barcodes

Laser engraving for barcodes finds applications in various industries, each benefiting from its unique advantages. Some common applications include:

1. Manufacturing and Automotive Industry

In the manufacturing and automotive sectors, laser-engraved barcodes are used for product traceability, inventory management, and quality control. By engraving barcodes directly onto components, manufacturers can easily track each item throughout the production process, ensuring accurate identification and efficient logistics.

2. Logistics and Warehousing

Barcode engraving is crucial for efficient inventory management and tracking in logistics and warehousing operations. By laser engraving barcodes on packages, pallets, or individual items, businesses can streamline their supply chain, reduce errors, and improve overall operational efficiency.

3. Retail and Point-of-Sale

In the retail industry, laser-engraved barcodes can be found on product packaging or labels. These barcodes enable quick and accurate scanning at the point-of-sale, optimizing checkout processes and enhancing customer experience. Laser engraving ensures that barcodes remain legible, reducing the chances of delays or errors during transactions.

4. Medical and Pharmaceutical

Laser engraving is widely used in the medical and pharmaceutical sectors for product identification and safety purposes. Barcodes engraved on medical devices, surgical instruments, or pharmaceutical packaging enable efficient tracking, inventory management, and adherence to regulatory requirements. The durability of laser-engraved barcodes ensures their readability in sterile environments and throughout the product’s lifespan.

Considerations for Laser Engraving Barcodes

When considering laser engraving for barcodes, it is important to keep a few factors in mind:

1. Material Compatibility

Ensure that the material you plan to engrave is compatible with laser technology. Different materials require specific laser settings and techniques for optimal results. Conduct thorough testing to verify the suitability of the material for laser engraving.

2. Barcode Size and Density

Consider the size and density requirements of your barcodes. Laser engraving offers the flexibility to create barcodes of varying sizes and densities. However, it is essential to ensure that the resulting barcode remains scannable and meets industry standards.

3. Compliance with Standards

Check if there are any industry or regulatory standards that apply to your barcode engraving requirements. Ensure that the laser engraving process you choose adheres to these standards, guaranteeing compatibility with scanning devices and compatibility across your supply chain.

4. Laser Engraving Equipment

Invest in high-quality laser engraving equipment that meets your specific needs. Consider factors such as laser power, speed, software capabilities, and maintenance requirements. Collaborate with reputable suppliers to ensure you choose the right equipment for your barcode engraving applications.

In conclusion, laser engraving for barcodes offers numerous benefits in terms of durability, precision, versatility, speed, and eco-friendliness. Its applications span across various industries, enabling efficient product identification, tracking, and inventory management. By considering important factors and utilizing the appropriate laser engraving equipment, businesses can harness the power of laser technology to optimize their barcode marking processes and enhance overall operational efficiency.