Laser Engraving for Automotive Parts

Laser engraving is a highly efficient and precise method of marking and personalizing automotive parts. With its ability to create permanent, high-quality markings, laser engraving has become increasingly popular in the automotive industry. This article will delve into the various aspects of laser engraving for automotive parts, including its benefits, applications, and the specific types of automotive parts that can be engraved.

Benefits of Laser Engraving for Automotive Parts

Laser engraving offers several key advantages over conventional marking methods commonly used in the automotive industry. These benefits include:

-

Durability: Laser engraving creates permanent markings that are highly resistant to wear, fading, and corrosion. This durability ensures that the markings on automotive parts remain legible and intact even under harsh environmental conditions.

-

Precision: Laser engraving technology allows for intricate and precise markings, ensuring that even the most complex designs and logos can be engraved with exceptional accuracy. This level of precision is crucial in maintaining the aesthetic appeal of the automotive parts.

-

Versatility: Laser engraving can be performed on a wide range of materials commonly used in automotive manufacturing, including metals, plastics, glass, and ceramics. This versatility makes it suitable for marking various automotive components, regardless of their composition.

-

Speed: Laser engraving is a fast and efficient process, particularly when compared to traditional methods such as mechanical engraving. This allows for increased productivity and shorter lead times in the production of automotive parts.

-

Flexibility: Laser engraving offers the flexibility to mark both flat and curved surfaces, making it suitable for a wide variety of automotive parts, including engine components, dashboards, door panels, and even tires.

Applications of Laser Engraving in the Automotive Industry

Laser engraving finds numerous applications in the automotive industry, contributing to both functional and decorative aspects of automotive parts. Some of the key applications include:

1. Identification and Branding

Laser engraving is commonly used to mark automotive parts with essential identification information, such as serial numbers, part codes, and batch numbers. This ensures traceability and assists in quality control processes throughout the manufacturing and assembly stages. Additionally, laser engraving allows automotive manufacturers to brand their products with logos and trademarks, enhancing brand recognition and adding a touch of elegance.

2. Personalization and Customization

With laser engraving, automotive parts can be personalized and customized to meet individual customer preferences. This is particularly relevant in the high-end automotive market, where customers seek unique and exclusive features. Laser engraving allows for the incorporation of personalized designs, patterns, and even text on various automotive parts, providing a sense of exclusivity and luxury.

3. Functional Markings

Laser engraving can also be used to create functional markings on automotive parts. For example, engine components can be engraved with calibration marks, alignment indicators, or measurement scales, aiding in precision assembly and maintenance. This ensures accurate alignment and proper functioning of the automotive parts, thus improving performance and reliability.

4. Aesthetic Enhancements

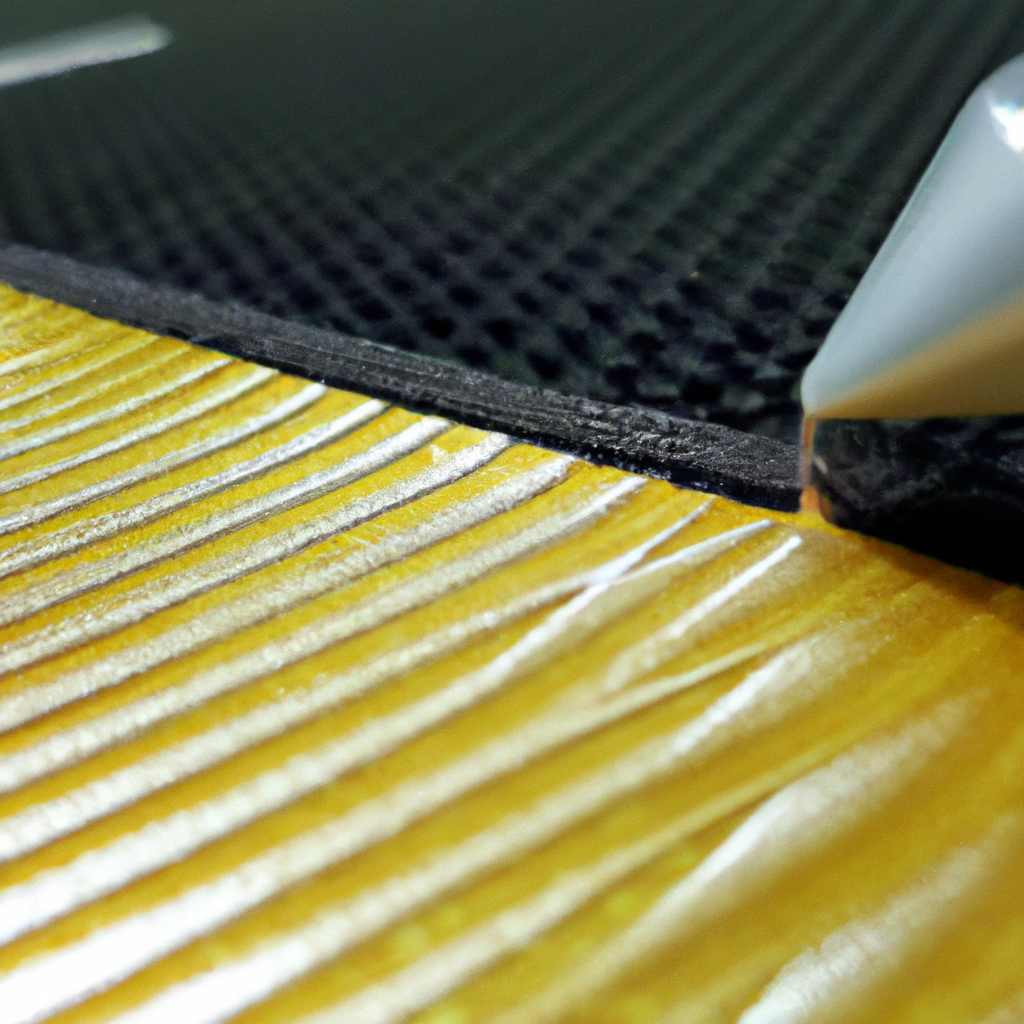

Laser engraving offers endless possibilities for enhancing the visual appeal of automotive parts. Intricate patterns, decorative motifs, and textured surfaces can be engraved on dashboards, steering wheels, and exterior body panels, adding a touch of sophistication and uniqueness to the vehicle’s design. Laser engraving also allows for the creation of visually striking contrasts by selectively removing coatings or anodized layers to reveal the underlying material.

Automotive Parts Suitable for Laser Engraving

Numerous automotive parts can benefit from laser engraving. Some examples include:

-

Engine Components: Laser engraving can be used to mark engine valves, cylinder heads, camshafts, and other components with identification codes or calibration markings.

-

Interior Components: Laser engraving can add personalized designs or logos on dashboards, door panels, and trim pieces, enhancing the interior aesthetics of the vehicle.

-

Exterior Body Panels: Laser engraving offers the opportunity to create intricate designs or graphics on exterior body panels, making the vehicle stand out from the crowd.

-

Exhaust Systems: Laser engraving can be used to create unique designs or brand logos on exhaust tips, enhancing their visual appeal.

-

Tires: Laser engraving on tires allows for the inclusion of brand logos, tire specifications, or custom patterns, providing a personalized touch to the vehicle’s wheels.

Conclusion

Laser engraving has emerged as a game-changer in the automotive industry, offering numerous benefits and applications for marking and personalizing automotive parts. Its durability, precision, versatility, speed, and flexibility make it a preferred choice for automotive manufacturers looking to enhance the functionality, aesthetics, and branding of their products. With its ability to create permanent and high-quality markings on a wide range of automotive parts, laser engraving has cemented its place as an indispensable tool in the automotive manufacturing process.

*Markdown format:

“`

Laser Engraving for Automotive Parts

Benefits of Laser Engraving for Automotive Parts

- Durability

- Precision

- Versatility

- Speed

- Flexibility

Applications of Laser Engraving in the Automotive Industry

1. Identification and Branding

2. Personalization and Customization

3. Functional Markings

4. Aesthetic Enhancements

Automotive Parts Suitable for Laser Engraving

- Engine Components

- Interior Components

- Exterior Body Panels

- Exhaust Systems

- Tires

Conclusion

“`