Expert Laser Engraving

Laser engraving is a highly precise and versatile technology that has gained immense popularity across various industries. It offers the ability to create intricate designs, markings, and engravings on a wide range of materials with exceptional accuracy. In this comprehensive guide, we will delve into the world of laser engraving, exploring its applications, benefits, and the process involved.

What is Laser Engraving?

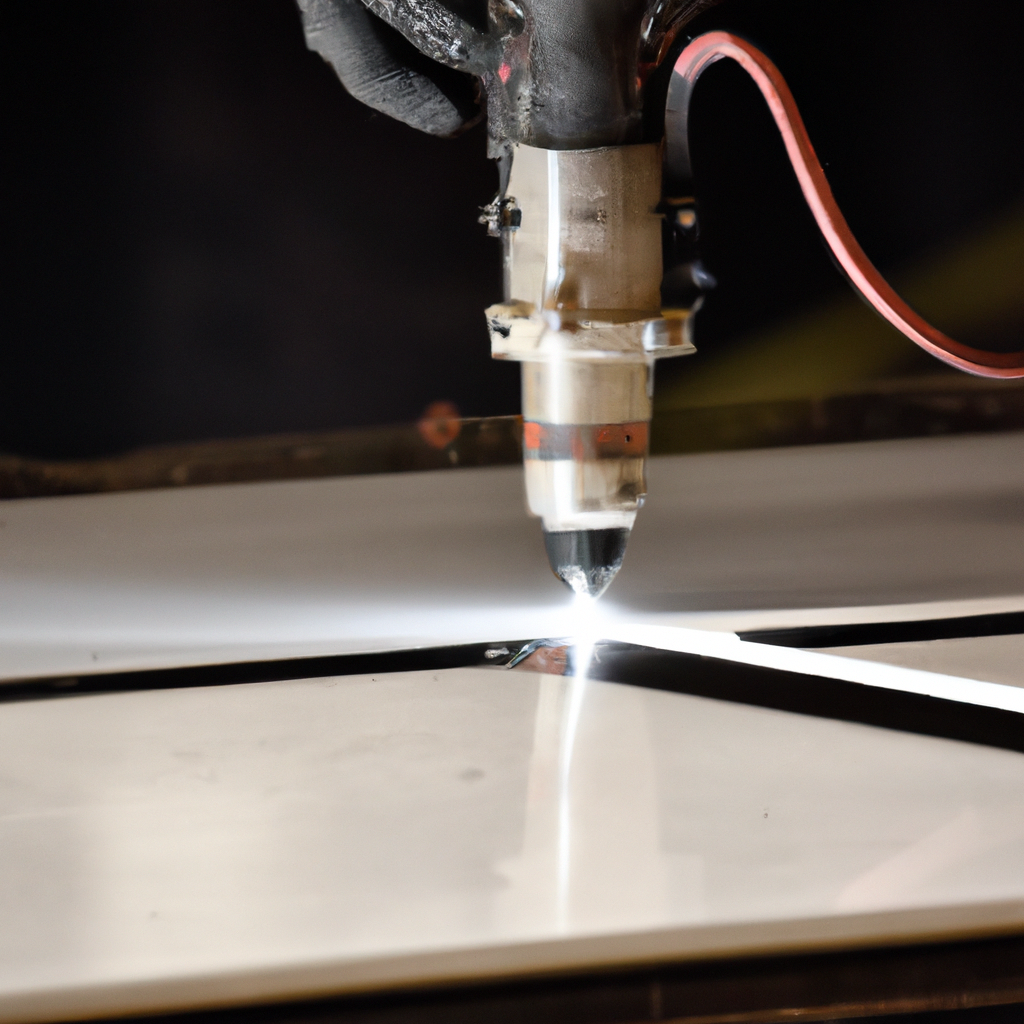

Laser engraving is a process that utilizes laser technology to etch designs, patterns, or text onto various materials. This precise and efficient technique involves the use of a high-powered laser beam that removes the top layer of the material, creating a permanent mark or engraving.

Applications of Laser Engraving

1. Personalization and Customization

Laser engraving offers endless possibilities for personalizing and customizing various products. It is commonly used in the production of personalized gifts, trophies, and awards, adding a unique touch to commemorate special occasions such as weddings, anniversaries, or corporate events.

2. Product Branding and Identification

Many businesses rely on laser engraving to brand their products with logos, serial numbers, or other markings. This ensures product authenticity and enhances brand recognition. It is particularly useful in industries like electronics, automotive, and jewelry where product identification and traceability are crucial.

3. Signage and Displays

Laser-engraved signs and displays have become increasingly popular due to their durability and professional appearance. From personalized nameplates to intricate signage for businesses or institutions, laser engraving provides a cost-effective and long-lasting solution.

4. Architectural and Interior Design

Laser engraving enables architects and interior designers to create stunning designs on various materials like wood, glass, or metal. From decorative panels to intricate room dividers, laser engraving adds a beautiful and unique touch to any space.

5. Industrial Applications

In the industrial sector, laser engraving is widely used for product marking, barcoding, and identification. It allows manufacturers to meet strict traceability requirements, ensuring product quality and compliance with industry standards.

Benefits of Laser Engraving

1. Precision and Accuracy

Laser engraving offers unparalleled precision and accuracy, allowing for intricate designs and fine details. The focused laser beam ensures consistent and sharp engravings, regardless of the complexity of the design or material.

2. Versatility

Laser engraving can be performed on a wide range of materials, including wood, acrylic, glass, leather, metal, and more. This versatility makes it an ideal choice for various applications, whether you’re engraving jewelry, signage, or industrial parts.

3. Durability and Longevity

Laser-engraved markings are highly durable and resistant to fading, wear, and tear. Unlike traditional engravings or prints, laser markings are less prone to damage from external factors such as moisture or sunlight, ensuring longevity and consistent quality.

4. Speed and Efficiency

Compared to traditional engraving methods, laser engraving is significantly faster and more efficient. The automated process allows for quick turnaround times, making it suitable for both small-scale projects and large-scale production runs.

5. Non-Contact Process

Laser engraving is a non-contact process, meaning the laser beam does not physically touch the material being engraved. This eliminates the risk of damage or distortion, ensuring precise and flawless engravings every time.

The Laser Engraving Process

-

Design Preparation: To begin the laser engraving process, a digital design file is created using specialized graphic design software. This design file specifies the exact dimensions, layout, and details of the desired engraving.

-

Material Selection: Different materials require specific laser settings to achieve optimal results. The material to be engraved is carefully selected based on its compatibility with laser engraving and the desired outcome.

-

Machine Setup: The laser engraving machine is set up according to the specifications of the material and desired engraving depth. The focal point of the laser beam is adjusted to ensure optimal focus and precision.

-

Engraving Execution: The material is securely placed in the laser engraving machine, and the design file is uploaded to the machine’s software. The laser beam then follows the path specified in the design file, removing material and creating the desired engraving.

-

Finishing Touches: After the engraving is complete, the material may require additional steps such as cleaning, polishing, or coating to enhance the appearance and durability of the engraving.

Conclusion

Laser engraving is a versatile and efficient technology that offers endless possibilities for customization, branding, and design. Its precision, durability, and non-contact process make it a preferred choice across various industries. Whether you’re looking to personalize a gift, brand your products, or create stunning architectural designs, laser engraving is an expert solution that guarantees exceptional results. Embrace the power of laser engraving and unlock a world of creativity and endless possibilities!