Advanced Laser Etching

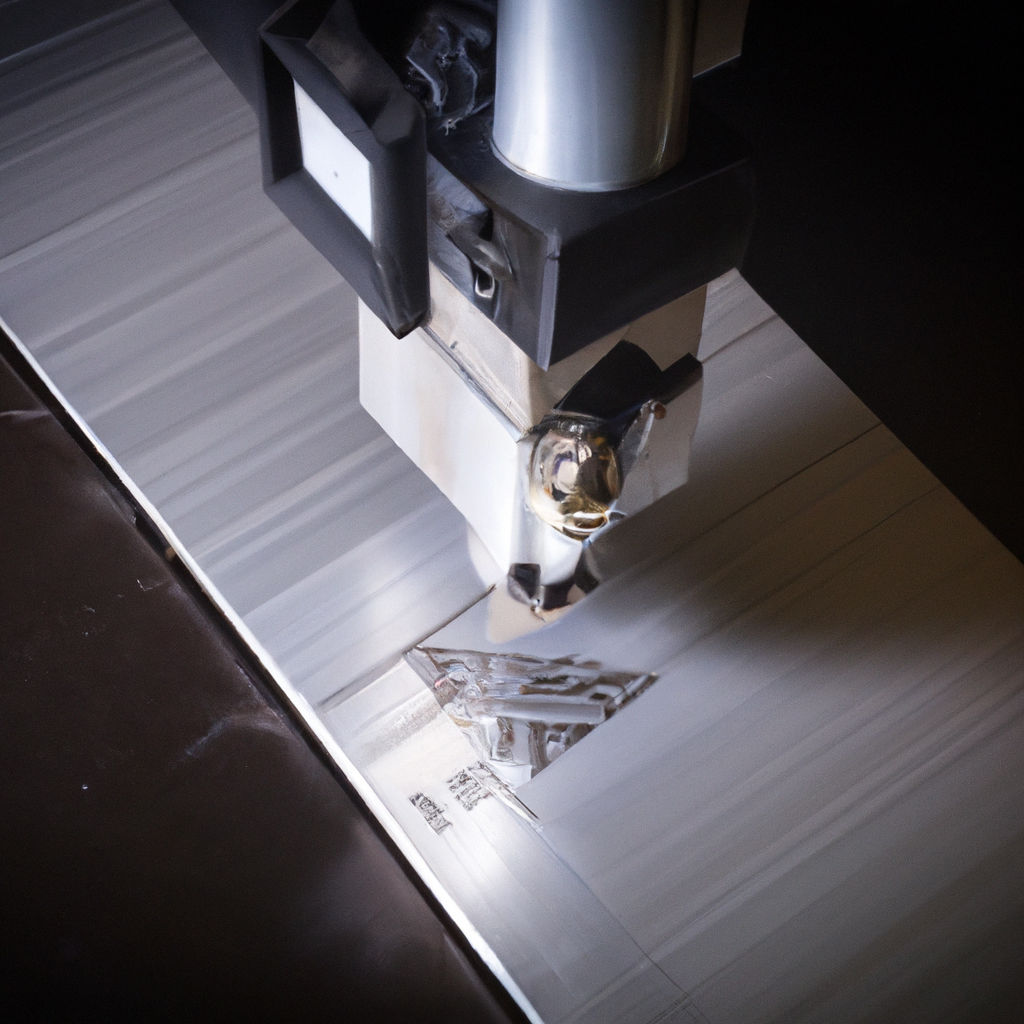

Laser etching has revolutionized various industries by providing precise and intricate designs on a wide range of materials. This advanced technique offers unparalleled flexibility and accuracy, making it a popular choice for many applications. In this article, we will delve into the world of advanced laser etching and explore its capabilities, benefits, and potential applications.

Understanding Laser Etching

Laser etching, also known as laser engraving, is a process that utilizes laser technology to create permanent, high-quality designs on various surfaces. By directing an intense laser beam onto the material, the surface undergoes controlled heating, vaporization, or melting, resulting in a precise etched pattern.

The Advantages of Advanced Laser Etching

-

Precision: One of the key advantages of advanced laser etching is its exceptional precision. The laser beam can be controlled with incredible accuracy, allowing for intricate and detailed designs that traditional methods simply cannot achieve.

-

Versatility: Laser etching can be performed on a wide range of materials, including metals, plastics, glass, wood, leather, and more. This versatility opens up endless possibilities for customization and personalization.

-

Durability: Laser-etched designs are highly durable and resistant to fading, scratching, or wearing off. This makes laser etching an ideal choice for creating long-lasting and professional-looking markings or designs.

-

Speed and Efficiency: Advanced laser etching is a rapid and efficient process that can be automated for large-scale production. This enables quick turnaround times, making it suitable for both small-scale customization and industrial applications.

-

Non-contact Process: Laser etching is a non-contact process, meaning that the material being etched remains untouched during the process. This eliminates the risk of damage or distortion, ensuring a clean and precise outcome.

Applications of Advanced Laser Etching

The applications of advanced laser etching are vast and diverse. Here are some areas where laser etching finds extensive use:

1. Personalization and Customization

Laser etching offers a unique opportunity to personalize and customize various products. From engraving names or initials on jewelry and accessories to adding intricate designs on electronics or gadgets, laser etching adds a touch of individuality and exclusivity.

2. Industrial Marking and Branding

In industrial settings, laser etching plays a crucial role in marking and branding products. This can include adding serial numbers, barcodes, logos, or other identification marks on manufactured items. Laser etching ensures permanent and highly legible markings that withstand harsh conditions.

3. Signage and Display

Laser etching is widely used in the signage and display industry. From creating intricate patterns on acrylic signs to etching detailed designs on glass or metal panels, laser etching provides a visually striking and durable solution for both indoor and outdoor applications.

4. Art and Design

Artists and designers also leverage advanced laser etching techniques to create unique and intricate artwork. By combining different materials and utilizing the precision of laser technology, artists can explore new creative possibilities and push the boundaries of traditional art forms.

5. Medical and Aerospace Industries

In the medical and aerospace industries, laser etching is employed for various purposes. It can be used to mark medical devices, surgical instruments, or components, ensuring traceability and compliance with industry regulations. Laser etching is also utilized for high-precision machining and manufacturing of aerospace components.

Choosing the Right Laser Etching System

To achieve the best results in advanced laser etching, it is crucial to select the right laser etching system. Consider the following factors when choosing a laser etching system:

-

Power and Wavelength: The power and wavelength of the laser system determine its capability to etch different materials. Ensure that the system you choose aligns with the materials you intend to etch.

-

Precision and Accuracy: Look for a laser system that offers high precision and accuracy. This will ensure that even the most intricate designs are etched with perfection.

-

Ease of Use: Consider the user-friendliness of the laser etching system. Look for features such as intuitive software interfaces and automated processes that enhance efficiency and ease of operation.

-

Safety Features: Laser systems can pose safety risks if not used correctly. Opt for a system that incorporates safety features such as enclosed workspaces, emergency stops, and laser safety certifications.

Conclusion

Advanced laser etching has revolutionized the way we personalize, brand, and manufacture various products. Its precision, versatility, durability, and speed make it an invaluable tool across a wide range of industries. By understanding the capabilities and applications of laser etching, you can harness its potential to enhance your products, designs, and manufacturing processes.