Laser Etching Solutions

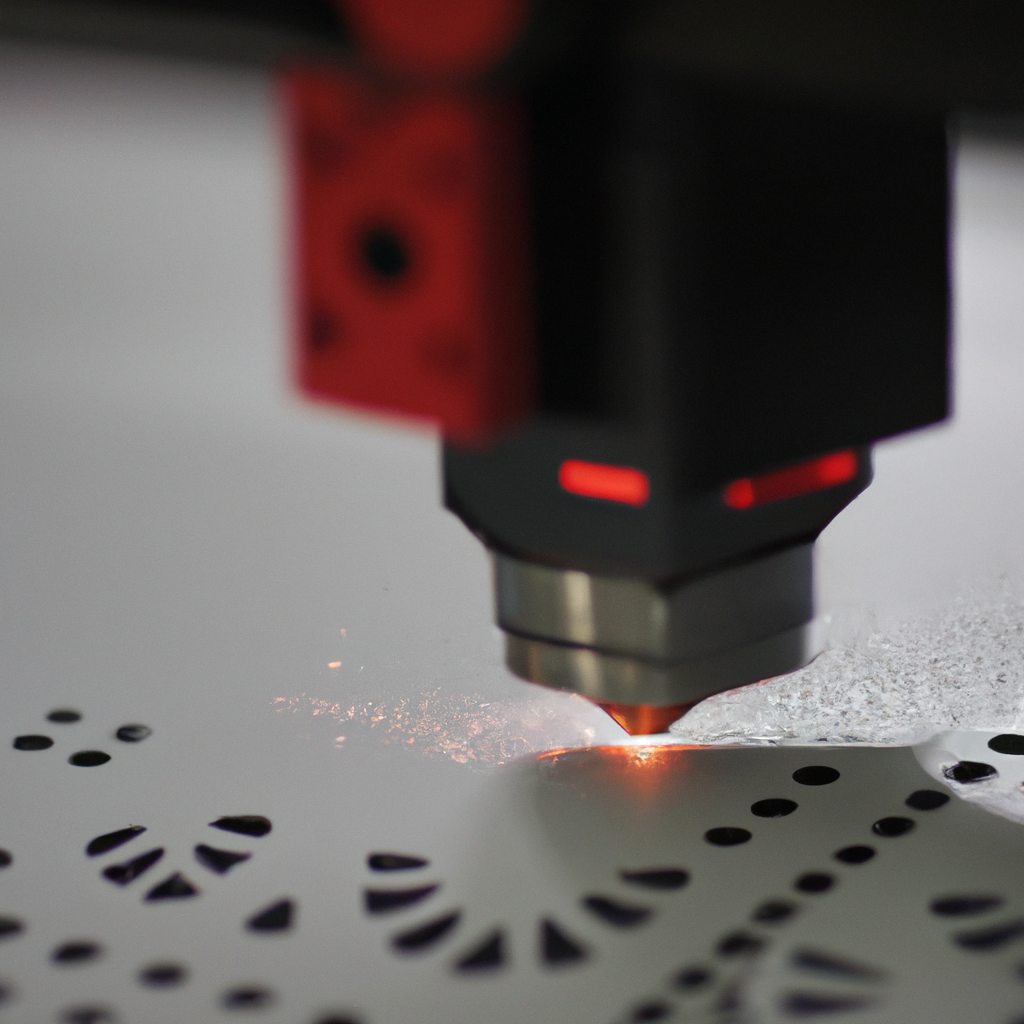

Laser etching, also known as laser engraving, is a process that utilizes laser technology to create precise and detailed markings on a wide range of materials. This versatile technique has gained significant popularity in various industries due to its ability to provide permanent and highly accurate markings. From personalized gifts to industrial applications, laser etching solutions offer exceptional results and numerous benefits. In this article, we will explore the advantages, applications, and considerations of laser etching.

Advantages of Laser Etching

-

Precision: Laser etching allows for meticulous and intricate details to be engraved on different materials. The laser beam can achieve an exceptionally high level of precision, resulting in clear and crisp markings. This makes it an ideal choice for branding, personalization, and intricate designs.

-

Durability: The etchings created by lasers are highly durable and resistant to fading, wear, and tear. Unlike traditional printing methods, laser etchings are not prone to being rubbed off or easily damaged. This durability is crucial for applications that require long-lasting markings, such as serial numbers, logos, or identification codes.

-

Versatility: Laser etching can be applied to a wide variety of materials, including metals, plastics, glass, wood, and even some fabrics. This versatility allows for endless possibilities in terms of materials, making it adaptable for various industries and applications.

-

Speed and Efficiency: Laser etching is a rapid and efficient process, especially when compared to traditional methods such as hand engraving. The speed at which laser etching can be performed makes it highly suitable for large-scale production and time-sensitive projects.

-

Non-contact Process: Laser etching is a non-contact process, meaning that the laser beam does not physically touch the material being engraved. This non-contact nature eliminates the risk of surface damage, distortion, or contamination, ensuring the integrity of the material remains intact.

Applications of Laser Etching

Laser etching solutions find applications in a wide range of industries and sectors. Here are some notable examples:

1. Manufacturing and Industrial Applications

In manufacturing and industrial settings, laser etching is commonly used for product identification, branding, and serialization. It allows manufacturers to mark their products with important information such as serial numbers, barcodes, model numbers, and logos. These markings aid in traceability, inventory management, and brand recognition.

2. Personalization and Giftware

Laser etching offers a unique and personalized touch to various gift items and keepsakes. It enables individuals to add names, messages, or custom designs to items like jewelry, photo frames, keychains, and trophies. Whether it’s for special occasions, corporate gifts, or personal mementos, laser etching provides a customizable and memorable option.

3. Automotive and Aerospace Industries

In the automotive and aerospace sectors, laser etching plays a vital role in part identification and traceability. It allows for accurate and permanent marking of components, making it easier to track their origins, manufacturing details, and maintenance requirements. Laser etching also assists in counterfeit prevention and quality control.

4. Medical and Surgical Instruments

Laser etching is widely used in the medical field for surgical instruments, implants, and medical devices. It enables precise and permanent marking of instruments with essential information like lot numbers, sizes, and sterilization indicators. This aids in maintaining proper inventory, enhancing patient safety, and streamlining processes in healthcare facilities.

5. Architectural and Interior Design

In architectural and interior design applications, laser etching offers endless possibilities for customization. It allows for intricate and detailed patterns, logos, or textures to be etched onto various materials such as glass, metal, or stone. Laser etching can be used to create stunning designs on decorative panels, signage, artwork, or even furniture.

Considerations for Laser Etching Solutions

When considering laser etching solutions, there are a few factors to keep in mind:

-

Material Compatibility: Ensure that the material you want to etch is compatible with laser technology. Different materials may require specific laser parameters or surface preparation to achieve satisfactory results.

-

Design and Artwork: Prepare your design or artwork in a digital format that can be easily imported into the laser etching software. Vector files, such as those in EPS or AI formats, are preferred as they maintain clarity and scalability.

-

Quality and Resolution: Determine the desired level of detail and resolution for your etchings. Higher resolution settings provide finer details but may increase processing time.

-

Safety Measures: Laser etching involves the use of high-powered lasers, so it is essential to follow safety guidelines and use appropriate protective equipment. This ensures the safety of operators and prevents potential hazards.

-

Maintenance and Support: Consider the maintenance requirements and availability of technical support for the laser etching equipment you choose. Regular maintenance and timely support can help maximize the lifespan and efficiency of your system.

In conclusion, laser etching solutions offer a myriad of advantages, making it a preferred choice for precise and durable markings. Its versatility caters to various industries, from manufacturing and automotive to personalization and interior design. However, it is important to consider factors such as material compatibility, design requirements, safety measures, and ongoing support when implementing laser etching solutions. By utilizing this advanced technology, businesses and individuals can achieve exceptional results and elevate their products and projects to new heights.